Description

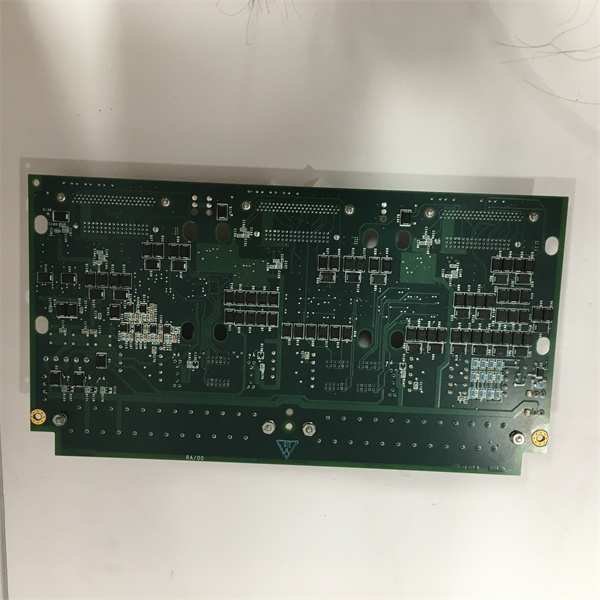

Product Overview

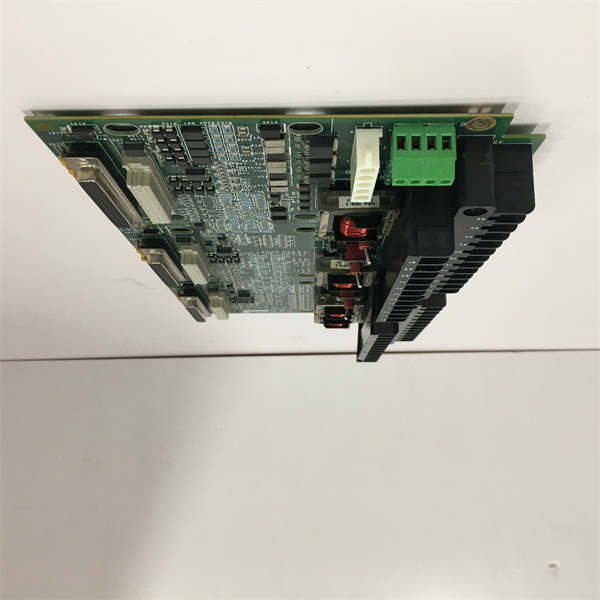

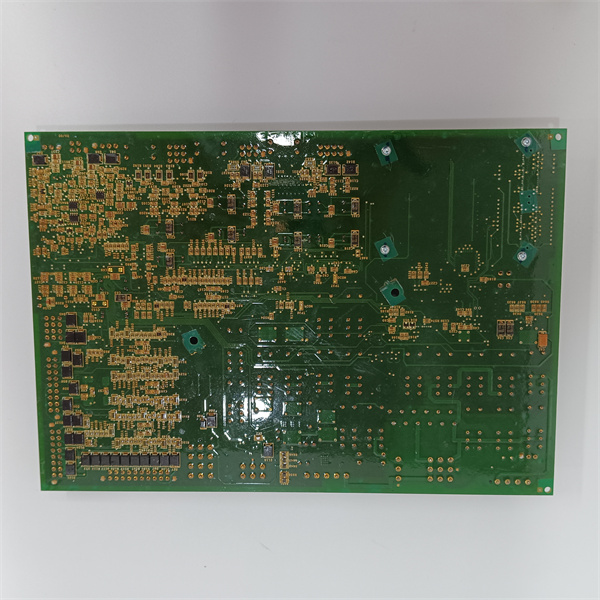

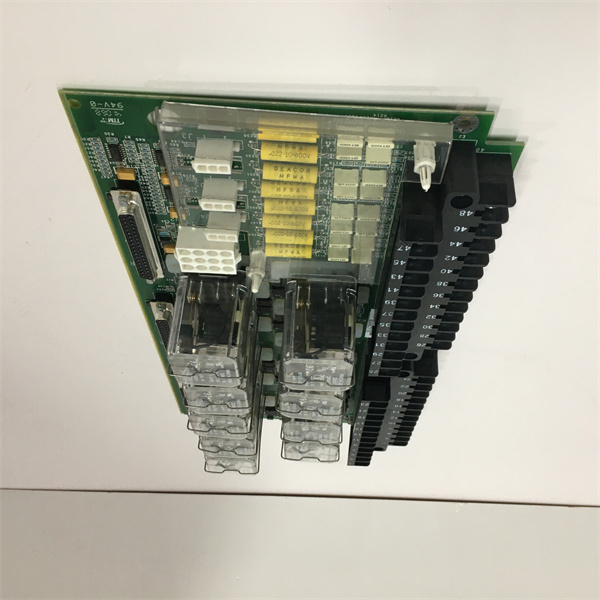

The GE IS410TRLYS1B is a relay output terminal board designed by General Electric, specifically tailored for use in simplex or TMR (Triple Modular Redundancy) configurations within the Mark VIeS series. This board plays a pivotal role in industrial control systems, especially those related to turbine operations. It provides integrity feedback on each relay circuit, which is crucial for ensuring the reliable operation of the overall system. The GE IS410TRLYS1B is engineered to meet the high – demand control requirements in industrial settings. It allows for accurate control and monitoring of electrical signals, making it an essential component for applications that need to manage various electrical loads. With its ability to interface with other components in the system, it helps in streamlining the control process and enhancing the overall efficiency of industrial automation.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS410TRLYS1B |

| Manufacturer | General Electric |

| Product Type | Relay Output Terminal Board |

| Series | Mark VIeS |

| Number of Channels | 12 form – C relays (12 DO) |

| Contact Ratings | 0.6 A at 125 V DC; 1.2 A at 48 V DC; 8 A at 24 V DC; 3 A at 120 – 240 VAC |

| I/O Contact Wetting & Fusing Configuration | Contacts 1 – 6 wetted & dual fused for solenoids, contacts 7 – 11 dry form – C, contact 12 separate I/O wetting |

| I/O Wetting Power Connector | Mate – n – lok receptacle (amp 350766 – 1) |

| Field Wiring Terminal Block | Barrier – type terminal blocks |

| Diagnostic Fault Detection | Power – up self test, I/O pack health, checks commanded output vs feedback, loss of contact wetting voltage, open fuse detection, and incorrect terminal board check |

| I/O Pack DC Control Power | 24 / 28 V DC, 19.8 W max, includes power to drive output relay coils |

| I/O Pack DC Power Connector | Micro mate – n – lok receptacle (amp 1445022 – 3) |

| I/O Pack Construction | Aluminum case |

| I/O Pack Health | Visual status leds, circuit health variables available to control logic |

| Ambient Operational Temperature | – 40 to 70 °C (- 40 to 158 °F) |

| Storage Temperature | – 40 to 85 °C (- 40 to 185 °F) |

IS200TSVCH1AED

Main Features and Advantages

Precise Relay Control

The GE IS410TRLYS1B offers 12 form – C relays, allowing for precise control over different electrical loads. The specific contact ratings ensure that it can handle a wide range of voltage and current requirements. For example, the ability to handle 8 A at 24 V DC makes it suitable for powering solenoids or other high – current devices in industrial setups.

Comprehensive Diagnostic Capabilities

This terminal board is equipped with an extensive diagnostic system. It conducts power – up self – tests, monitors the health of the I/O pack, and checks the commanded output against the feedback. In case of issues like loss of contact wetting voltage or open fuse detection, it can quickly identify the problem. This not only reduces downtime but also simplifies the troubleshooting process for maintenance personnel.

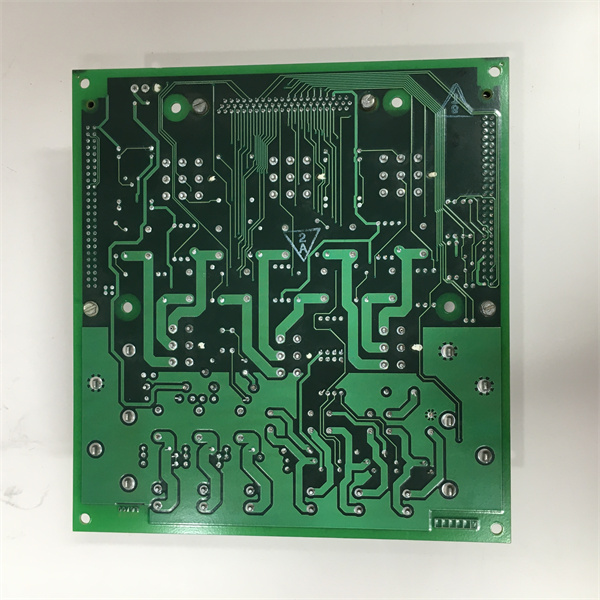

Durable Construction

With an aluminum – cased I/O pack, the GE IS410TRLYS1B is built to withstand harsh industrial environments. The robust construction protects the internal components from physical damage, vibrations, and electromagnetic interference. This durability ensures long – term reliable operation, even in challenging conditions.

Application Field

Power Generation

In power plants with gas turbines, the GE IS410TRLYS1B is used to control various auxiliary systems. For instance, it can manage the relays that control the opening and closing of valves in the fuel supply system. By providing accurate control signals, it helps in optimizing the fuel flow, ensuring the efficient operation of the gas turbine and stable power generation.

Industrial Manufacturing

In manufacturing facilities, this terminal board can be employed to control the electrical relays of motors in conveyor systems. It can precisely regulate the start – stop and speed of the motors, enhancing the overall efficiency of the production line. Additionally, in processes that require precise control of solenoid – actuated machinery, the GE IS410TRLYS1B can be relied upon to deliver accurate and reliable control signals.

Process Control

For industries involved in chemical or petrochemical processes, the GE IS410TRLYS1B is used to control the relays associated with pumps and compressors. It ensures that these critical components operate smoothly, maintaining the integrity of the process. The board’s ability to provide integrity feedback on relay circuits is especially valuable in such applications where any malfunction could lead to significant production losses or safety hazards.

Related Products

- IS410TRLYS1D: A related relay output terminal board, which might have differences in features such as the number of channels or contact ratings. It could be a variation designed for specific applications with different electrical load requirements compared to the GE IS410TRLYS1B.

- IS420UCSBH1A: A 燃机控制模块 from GE, which is used in a different aspect of the industrial control system. While the GE IS410TRLYS1B focuses on relay output and control, the IS420UCSBH1A is more centered around controlling and monitoring gas – fired generators, but they can work together in a comprehensive industrial automation setup.

- IS420UCSBH4A: Another industrial digital I/O module controller. It may have different input/output configurations and capabilities compared to the GE IS410TRLYS1B. It can be used in scenarios where a different mix of digital input and output functions is required, but it can also be integrated with the GE IS410TRLYS1B in a larger system.

- IC695CPL410 – ABAG: A GE Fanuc control module. It serves a different control purpose, perhaps more focused on overall system control and coordination, while the GE IS410TRLYS1B is specialized in relay – based output control. However, they can be part of the same industrial control infrastructure.

- IS410SRLYS2A: A controller module that likely has similarities in terms of being related to relay – based control, but may have different specifications or be designed for a different subset of industrial applications compared to the GE IS410TRLYS1B.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS410TRLYS1B, ensure that the installation area is clean and free from dust and debris. Verify that the power supply voltage matches the requirements of the board, which is 24 / 28 V DC for the I/O pack DC control power. Check the wiring connections in the simplex or TMR configuration to ensure they are correct and secure. Also, make sure that the ambient temperature of the installation site is within the operational range of – 40 to 70 °C.

Maintenance recommendations: Regularly monitor the visual status LEDs on the GE IS410TRLYS1B to check the health of the I/O pack. Periodically inspect the barrier – type terminal blocks for any signs of loose connections or corrosion. In case of a diagnostic fault, refer to the detailed diagnostic fault detection capabilities of the board, such as checking for open fuse detection or incorrect terminal board status. Keep the board clean to prevent dust accumulation, which could affect its performance over time.

Maintenance recommendations: Regularly monitor the visual status LEDs on the GE IS410TRLYS1B to check the health of the I/O pack. Periodically inspect the barrier – type terminal blocks for any signs of loose connections or corrosion. In case of a diagnostic fault, refer to the detailed diagnostic fault detection capabilities of the board, such as checking for open fuse detection or incorrect terminal board status. Keep the board clean to prevent dust accumulation, which could affect its performance over time.

Product Guarantee

General Electric stands firmly behind the GE IS410TRLYS1B with a comprehensive product guarantee. The board is manufactured using high – quality materials and advanced manufacturing techniques, ensuring its reliability. GE provides a standard warranty period, during which any defects in materials or workmanship will be rectified at no cost to the customer. Their team of technical experts is available to offer support for installation, configuration, and troubleshooting. In case of any issues with the GE IS410TRLYS1B, customers can reach out to GE’s customer service, who will work promptly to resolve the problem. This commitment reflects GE’s confidence in the quality of the product and its dedication to providing a seamless experience for industrial users.