Description

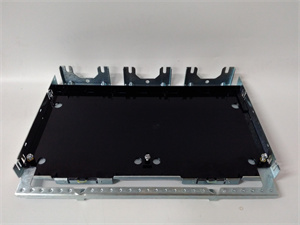

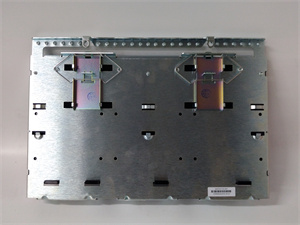

Product Overview

The GE IS230TVBAH2A is a high – power dual – supply driver module by General Electric, designed to play a crucial role in industrial control systems. It’s part of GE’s comprehensive range of industrial automation products, known for their reliability and advanced functionality. This module is engineered to drive high – current and high – power applications, making it suitable for scenarios where robust power management and precise control are essential.

The IS230TVBAH2A has the ability to detect abnormal conditions in the circuit. For instance, when it detects a voltage of 7V at input 1, it determines that the circuit is short – circuited. In such a case, it immediately outputs a shutdown signal through the optocoupler. This action shuts down the module, causing its 5 – terminal output to go low. This low output places the GE terminals of the IGBT (Insulated – Gate Bipolar Transistor) in a negative bias, ensuring the reliable shutdown of the IGBT. This protection mechanism is vital as it prevents the base pole of the IGBT from burning out and suffering a breakdown.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS230TVBAH2A |

| Manufacturer | GE |

| Product Type | High – Power Dual – Supply Driver Module |

| Power Supply | [Specify power supply requirements if available, e.g., dual – voltage input for redundancy] |

| Input Voltage Detection Threshold | 7V (for short – circuit detection) |

| Output Signal for Shutdown | Low – level signal (at 5 – terminal) to bias IGBT negatively |

| Fault Output Terminal | Terminal 8 (goes low to indicate output error) |

| Operating Temperature Range | – 20 °C to 70 °C (typical for industrial modules) |

| Communication Interfaces | [List any communication interfaces if applicable, e.g., digital I/O for status reporting] |

| Dimensions | [Provide dimensions if available, e.g., length x width x height in mm] |

| Weight | [Mention weight if known] |

IS230TVBAH2A

Main Features and Advantages

Precise Fault Detection and Protection

The GE IS230TVBAH2A excels in its ability to accurately detect short – circuits in the circuit. Once a short – circuit is detected, its rapid shutdown mechanism ensures the safety of connected components, especially the IGBT. This not only protects the expensive IGBT from damage but also safeguards the entire industrial control system from potential cascading failures due to electrical faults.

High – Power Handling Capability

Designed for high – current and high – power applications, this module can efficiently drive heavy – duty loads. It can handle the power requirements of industrial equipment such as large – scale motors or high – power actuators, providing stable and reliable power delivery. This makes it an ideal choice for industries where high – power operations are the norm, like manufacturing plants and power – generation facilities.

Compatibility with Industrial Systems

The IS230TVBAH2A is engineered to be compatible with a wide range of industrial control systems. It can be easily integrated into existing setups, whether they are part of a complex manufacturing process or a power – management system. This compatibility allows for seamless operation within different industrial environments, reducing the need for extensive system re – engineering when incorporating this module.

IS230TVBAH2A

Application Field

In the manufacturing industry, the GE IS230TVBAH2A is used in high – power machinery control. For example, in an automotive manufacturing plant, it can be used to drive the motors that power large robotic arms used in vehicle assembly. The module’s ability to handle high – current loads and provide precise fault protection ensures the smooth and safe operation of these critical pieces of equipment.

In power – generation facilities, the IS230TVBAH2A plays a vital role in controlling high – power components. In a gas – turbine power plant, it can be used to drive the actuators that control the fuel injection system or the turbine blades’ pitch. By providing reliable power and quick fault detection, it contributes to the stable and efficient operation of the power – generation process.

It also finds applications in heavy – duty material handling equipment. In a large – scale warehouse or a port, the module can be used to drive the motors of cranes or conveyor belts. Its high – power handling capacity and fault – protection features are essential for ensuring the continuous and safe operation of these material – handling systems.

Related Products

- GE IS230TVBAH4A: This is a vibration input assembly by GE. While the IS230TVBAH2A focuses on high – power dual – supply driving and fault protection, the IS230TVBAH4A is designed for monitoring and controlling machinery vibrations. It can be used in conjunction with the IS230TVBAH2A in systems where both power management and vibration monitoring are crucial, such as in some industrial rotating equipment setups.

- GE IC697CPM925: A programmable logic controller (PLC) CPU module. The IS230TVBAH2A can be integrated with the IC697CPM925 in industrial control systems. The PLC can send control commands to the IS230TVBAH2A based on various input signals, and the IS230TVBAH2A can then execute the power – driving functions accordingly, enabling more complex and automated control of industrial processes.

- GE DS200DMCBG1AED: A digital motion control board. In applications where precise motion control is required along with high – power driving, the IS230TVBAH2A can work in tandem with the DS200DMCBG1AED. For example, in a robotic manufacturing cell, the DS200DMCBG1AED can control the motion of the robot arms, while the IS230TVBAH2A provides the necessary high – power drive to move the heavy – duty components of the robotic system.

- GE VME – PMC – CADDY: A carrier module for PMC cards. The IS230TVBAH2A can potentially be integrated into a system that uses the VME – PMC – CADDY if there is a need to expand the system’s functionality. For instance, if additional power – driving capabilities are required in a VME – based industrial control system, the IS230TVBAH2A can be incorporated through the appropriate PMC – based interface on the VME – PMC – CADDY.

- GE IS230TVBAH2A’s Upgraded Versions (if available): These would likely have enhanced features such as improved power – handling efficiency, more advanced fault – detection algorithms, or better compatibility with newer industrial communication protocols. They can be used as a direct replacement for the IS230TVBAH2A in applications where performance upgrades are needed without major changes to the overall system architecture.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS230TVBAH2A, ensure that the power supply to the system is turned off to avoid electrical hazards. Check the compatibility of the module with the existing control system, including verifying the power supply requirements, communication interfaces, and mechanical mounting options. Familiarize yourself with the installation manual provided by GE, which will detail the correct wiring and connection procedures. Make sure that all the components in the system, especially those that the IS230TVBAH2A will be connected to, are in good working condition.

Maintenance recommendations: Regularly inspect the GE IS230TVBAH2A for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the operating temperature of the module, as it should remain within the specified – 20 °C to 70 °C range. Check the fault output terminal (terminal 8) periodically to ensure that no undetected faults are present. If there are any communication interfaces on the module, use diagnostic tools to verify the integrity of the data transmission. Periodically clean the module to remove dust and debris, as these can affect the performance and heat dissipation of the module. If a fault is detected, refer to the GE – provided troubleshooting guide or contact GE’s technical support for assistance.

Maintenance recommendations: Regularly inspect the GE IS230TVBAH2A for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the operating temperature of the module, as it should remain within the specified – 20 °C to 70 °C range. Check the fault output terminal (terminal 8) periodically to ensure that no undetected faults are present. If there are any communication interfaces on the module, use diagnostic tools to verify the integrity of the data transmission. Periodically clean the module to remove dust and debris, as these can affect the performance and heat dissipation of the module. If a fault is detected, refer to the GE – provided troubleshooting guide or contact GE’s technical support for assistance.

Product Guarantee

GE offers a comprehensive product guarantee for the GE IS230TVBAH2A. The module typically comes with a standard warranty period, during which GE will repair or replace the module free of charge if it is found to have defects in materials or workmanship. GE also provides professional technical support to assist customers with installation, configuration, and troubleshooting. Their team of experts is available to answer any questions related to the IS230TVBAH2A and help customers optimize its performance in their specific industrial applications. This commitment to quality and after – sales support gives customers the confidence to rely on the GE IS230TVBAH2A for their critical industrial control needs.