Description

Product Overview

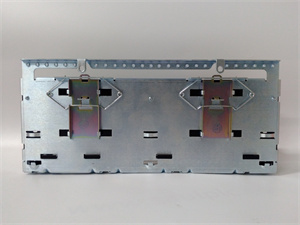

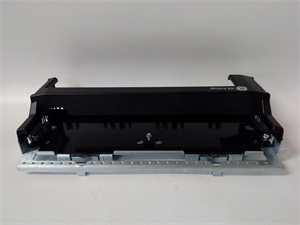

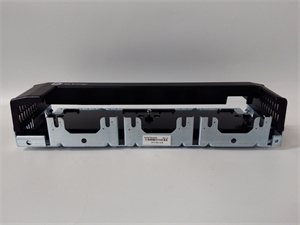

The GE IS230TBAIH2C is an analog I/O terminal board meticulously crafted by General Electric as an integral component of the Mark VI series, predominantly utilized in GE Speedtronic gas turbine control systems. In the complex landscape of industrial automation, this module plays a pivotal role in enabling seamless communication between various field devices and the central control system.

Designed with precision, the IS230TBAIH2C is equipped to handle a diverse range of analog input and output signals. It features 10 analog inputs that can interface with two – wire, three – wire, four – wire transmitters, or those with external power sources. This flexibility makes it adaptable to different sensor types and setups commonly found in industrial environments. The 2 analog outputs offer configurable current settings, either 0 – 20 mA or 0 – 200 mA, providing the versatility required for driving various actuators and control elements. Its presence in the Mark VI series ensures that it is well – integrated into a comprehensive control solution, enhancing the overall reliability and efficiency of industrial processes, especially those related to gas turbine operations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS230TBAIH2C |

| Manufacturer | GE |

| Product Type | Analog I/O Terminal Board |

| Number of Channels | 10 analog inputs, 2 analog outputs |

| Input Span | 1 – 5 V DC |

| Outputs | 24 V outputs |

| Maximum Lead Resistance | 15 ω |

| Output Load | 500 ω |

| Analog Output Current | 0 – 20 mA or 0 – 200 mA (configurable) |

| Operating Temperature | – 30 to 65 °C |

| Size | 10.16 cm wide x 33.02 cm |

| Mounting Type | [Describe the specific mounting method if available] |

| Input Voltage Protection | Protected by noise suppression circuitry |

| Redundancy Options | Supports simplex and triple modular redundant (TMR) applications |

| Number of DC – 37 Pin Connectors | 3 (for connection to I/O processors) |

| Weight | 1.14 kg |

| Communication Protocols | Indirectly interfaces with systems using industrial communication protocols via I/O processors |

IS230TBAIH2C

Main Features and Advantages

Multiple Input/Output Configurations

The GE IS230TBAIH2C offers a wide array of input and output configurations. With 10 analog inputs compatible with different types of transmitters and 2 analog outputs with configurable current ranges, it can be tailored to meet the specific requirements of diverse industrial applications. Whether it’s connecting to a variety of sensors in a power plant or actuators in an industrial manufacturing process, this board can adapt, ensuring seamless integration and operation.

Noise Suppression

Both the inputs and outputs of the IS230TBAIH2C are equipped with noise suppression circuitry. In industrial settings, electrical noise is a common issue that can disrupt the accuracy of signals. This built – in noise suppression feature ensures that the input signals are cleanly captured and the output signals are precisely transmitted, enhancing the reliability and stability of the control system. By reducing the impact of electrical interference, it helps in maintaining the integrity of the data being processed, leading to more accurate control decisions.

Redundancy Support

The board supports both simplex and triple modular redundant (TMR) applications. In critical industrial processes, such as power generation using gas turbines, system reliability is of utmost importance. The TMR configuration, for example, provides a high level of redundancy. In TMR setups, the input signals for the r, s, and t controls are distributed to three connections, and the outputs combine the currents of three connected output drivers. This redundancy significantly reduces the risk of system failure due to component malfunctions, ensuring continuous and stable operation of the industrial control system.

Easy Installation and Configuration

Installation of the GE IS230TBAIH2C is straightforward. Input and output wires can be directly attached to the two I/O terminal blocks on the board, each having 24 terminals that can accommodate wires up to #12 AWG and are secured with two screws. Configuration is also made simple through the use of jumpers. Jumpers can be used to select between current or voltage inputs, determine how the return is connected, choose the input current range, and adjust the output current settings. This ease of installation and configuration reduces the time and effort required for system setup and maintenance, minimizing downtime.

IS230TBAIH2C

Application Field

In power generation plants, the GE IS230TBAIH2C is crucial for gas turbine control. It interfaces with various sensors that monitor parameters such as temperature, pressure, and flow within the gas turbine system. The analog inputs of the board collect data from these sensors, and the control system can then use this information to regulate the operation of the turbine, ensuring optimal power generation efficiency. For example, it can adjust the fuel flow to the turbine based on the temperature readings, maintaining the correct combustion conditions.

Oil and gas facilities also rely heavily on the IS230TBAIH2C. In oil refineries, it can be used to control the operation of pumps and valves. The analog outputs can be used to drive actuators that open or close valves, controlling the flow of oil and gas through the pipelines. In gas processing plants, it interfaces with sensors that detect gas composition and pressure. Based on the input signals, the board can trigger control actions to ensure safe and efficient gas processing operations.

Industrial manufacturing plants that use gas turbines for power or process control benefit from the GE IS230TBAIH2C as well. It can be used to control the speed of machinery, such as conveyor belts or production line equipment. By accurately capturing analog input signals from sensors and providing precise analog output signals for control, it helps in maintaining consistent production quality and optimizing production processes.

Related Products

- IS230TNIAIH2C: This is a successor or an updated version of the IS230TBAIH2C. It may offer enhanced features, such as improved signal processing capabilities or additional input/output options. While the IS230TBAIH2C is a reliable analog I/O terminal board, the IS230TNIAIH2C could be a better fit for applications that require more advanced functionality or higher performance.

- IS420UCSBS1A: A safety – oriented controller module. In an industrial control system, the IS230TBAIH2C can feed analog input data to the IS420UCSBS1A. The controller module then processes this data and may send control signals back to the IS230TBAIH2C for actuation. For example, in a gas turbine safety system, the IS230TBAIH2C provides sensor data, and the IS420UCSBS1A makes decisions based on that data to ensure safe operation.

- IC697MDL652: A discrete input module. Unlike the analog – focused IS230TBAIH2C, the IC697MDL652 deals with digital input signals. However, in a comprehensive industrial control setup, both modules can co – exist. The IC697MDL652 can handle digital signals from sensors like limit switches, while the IS230TBAIH2C manages analog signals from sensors such as temperature or pressure transducers.

- DS200RTBAG2AFB: A relay terminal board. The DS200RTBAG2AFB is used for switching and distributing electrical signals, often based on control commands. In some industrial scenarios, the IS230TBAIH2C can provide the analog input data that is processed by a control system, which then sends commands to the DS200RTBAG2AFB to actuate relays and control electrical devices.

- IS230TBCI2CG01: Another module in the GE product line. It may have a different function, perhaps more focused on a specific aspect of industrial control, like digital communication or a different type of I/O handling. In a complex industrial control system, the IS230TBAIH2C and IS230TBCI2CG01 can work together, with each module performing its specialized task to ensure the overall system functions smoothly.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS230TBAIH2C, ensure that all power sources in the system are turned off to prevent electrical shock. Thoroughly inspect the board for any visible signs of damage during transit. Verify that the input and output devices to be connected are compatible with the board’s specifications, such as voltage and current ranges. Also, make sure the mounting location has sufficient space and meets the environmental requirements, considering the – 30 to 65 °C operating temperature range of the board. Prepare the necessary tools for attaching the wires to the terminal blocks.

Maintenance recommendations: Regularly check the IS230TBAIH2C for any signs of overheating, such as discoloration of the board or components. Inspect the connections of the input and output wires to ensure they are secure and free from corrosion. Monitor the operation of the board by periodically checking the accuracy of the input and output signals. If any issues are detected, refer to the GE product manual for guidance on troubleshooting. In case of a component failure, replace the faulty part following the proper procedures. Keep the board clean from dust and debris, as these can affect the performance of the electrical components over time.

Product Guarantee

GE is committed to the quality of the GE IS230TBAIH2C. The board is manufactured to high – quality standards and undergoes rigorous testing to ensure its reliability in industrial applications. In the event of a defect in materials or workmanship during the warranty period, GE will provide repair or replacement services at no cost to the customer. Their dedicated technical support team is available to assist with any installation – related questions, as well as to troubleshoot any issues that may arise during the board’s operation. This commitment to quality and customer support reflects GE’s confidence in the IS230TBAIH2C and its ability to meet the demanding requirements of industrial control systems, providing peace of mind to users relying on this critical component for their operations.