Description

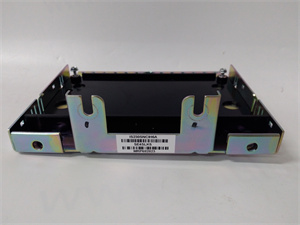

Product Overview

The GE IS230SNCIH6A is a high – performance module by General Electric, playing a pivotal role in industrial control and automation systems. It is designed to function as a key component within DCS (Distributed Control Systems) setups, especially in applications related to gas turbines and other industrial processes.

This module serves multiple critical functions. It acts as an input/output interface, facilitating seamless communication between PLCs (Programmable Logic Controllers) and various industrial field control or detection components. With a wide range of interface options, including different types of input (such as DC, AC, and AC – DC) and output (like transistor, thyristor, and relay outputs), it can adapt to diverse load requirements. The GE IS230SNCIH6A also features built – in Ethernet user – enabled communication, supporting SRTP and Modbus TCP/IP application protocols. This enables real – time data exchange and connection with other systems, enhancing overall system efficiency and control capabilities. It is an integral part of GE’s comprehensive suite of industrial automation products, offering reliable and flexible solutions for industries aiming to optimize their operations and improve productivity.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS230SNCIH6A |

| Manufacturer | General Electric |

| Product Type | Input/Output and Communication Module |

| Operating Voltage | 220 V |

| Output Frequency | 50 – 51 Hz |

| Communication Protocols | SRTP, Modbus TCP/IP |

| Input Types | DC, AC, AC – DC |

| Output Types | Transistor, Thyristor, Relay |

| Protection Rating | IP65 |

| Bus Current Requirement | 480 mA |

| Heat Dissipation | 12 W |

| Memory Capacity | 50 MB |

| Scan Time | Fast |

| Number of Communication Ports | 7 |

| Programming Interface | USB |

| Programming Software | Proficy Logic Developer PLC – Machine Edition |

| Supported Programming Languages | Ladder Diagram (LDI), Instruction List (IL), Structural Text (ST), C Block |

IS230SNCIH6A

Main Features and Advantages

Versatile I/O Interfaces

The GE IS230SNCIH6A offers a variety of input and output interface types. The multiple input options like DC, AC, and AC – DC inputs can accommodate different sensor and signal sources in industrial settings. For output, the availability of transistor, thyristor, and relay outputs allows for connection to a wide range of loads. Transistor outputs are suitable for high – frequency, low – power loads, while thyristor outputs are designed for high – frequency, high – power loads. Relay outputs, on the other hand, are ideal for low – frequency loads. This versatility ensures compatibility with diverse industrial equipment and processes, making it easier to integrate into existing systems.

Robust Communication Capabilities

With built – in Ethernet support for SRTP and Modbus TCP/IP protocols, the module enables reliable and fast data transfer. The 7 communication ports, including local expansion and Ethernet remote I/O ports, provide extensive connectivity options. This allows for seamless integration with other devices in a distributed control system. Whether it’s communicating with other controllers, sensors, or actuators, the GE IS230SNCIH6A ensures real – time data exchange, enhancing system responsiveness and control accuracy.

Scalable and Flexible Design

It has a scalable processing power, which means users can start with a configuration that meets their current needs and later expand the system without the need to change the software. This is highly beneficial for industries where requirements may evolve over time. Additionally, it supports multiple programming languages such as LDI, IL, ST, and C Block through the Proficy Logic Developer PLC – Machine Edition software. This flexibility in programming allows engineers with different backgrounds and preferences to develop control programs tailored to their specific applications.

Application Field

Power Generation

In power plants, especially those with gas turbines, the GE IS230SNCIH6A is used to monitor and control various parameters. It can interface with sensors that measure temperature, pressure, and flow in the gas turbine system. By processing the data from these sensors, it can control the operation of valves, pumps, and other equipment to ensure efficient power generation. For example, it can adjust the fuel supply to the gas turbine based on real – time temperature and pressure readings, optimizing combustion efficiency and power output.

Industrial Manufacturing

In manufacturing facilities, the module is used in automated production lines. It can control the movement of robotic arms, conveyor belts, and other machinery. For instance, it can receive input signals from proximity sensors on a conveyor belt to control the speed and start/stop of the belt. In robotic applications, it can process feedback from sensors on the robotic arm to ensure precise movement and accurate assembly of products, improving production quality and efficiency.

Oil and Gas

In the oil and gas industry, the GE IS230SNCIH6A is applied in processes such as oil refining and gas processing. It can be used to control the operation of pumps, compressors, and other equipment in the pipelines. By monitoring pressure, flow rate, and other parameters, it can prevent over – pressure situations, leaks, and ensure the safe and efficient transportation of oil and gas products.

Related Products

- GE IS420ESWBH2A: Another module by GE, likely with different functions or a different focus. It may complement the GE IS230SNCIH6A in a larger industrial control system, perhaps handling different types of signals or providing additional processing capabilities.

- GE QuickPanel Control: This product can be integrated with the GE IS230SNCIH6A to combine control and visualization on one platform. By using Proficy Machine Edition software, it offers flexible and scalable performance, enhancing the overall user experience and control interface for the system.

- GE PLC – Series XYZ: A series of PLCs that can work in tandem with the GE IS230SNCIH6A. The module can be connected to these PLCs to expand their I/O capabilities and communication options, enabling more complex control operations in industrial settings.

- GE Ethernet Communication Modules: These modules can further enhance the communication capabilities of the GE IS230SNCIH6A. They may support additional communication protocols or provide higher – speed data transfer, improving the module’s performance in large – scale industrial networks.

- GE Proficy Logic Developer (Upgraded Version): An updated version of the programming software used with the GE IS230SNCIH6A. It may offer more advanced features, better debugging tools, and enhanced compatibility with the latest operating systems, making programming and system development more efficient.

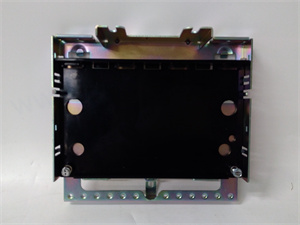

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS230SNCIH6A, carefully check the installation environment. Ensure that the temperature and humidity levels are within the specified range for the module. Verify the power supply voltage to match the 220 V requirement. Inspect all connection ports for any signs of damage. Make sure to have the necessary tools for installation, such as screwdrivers and wire strippers. Also, plan the physical layout of the module in the control cabinet to ensure proper ventilation and easy access for future maintenance.

Maintenance recommendations: Regularly clean the GE IS230SNCIH6A to remove dust and debris, as these can affect its performance over time. Monitor the module’s operating temperature and check for any signs of overheating. Periodically test the communication ports to ensure seamless data transfer. If any issues arise, refer to the detailed product manual provided by GE. Additionally, keep the software updated to the latest version to benefit from bug fixes and new features.

Product Guarantee

General Electric stands firmly behind the quality of the GE IS230SNCIH6A. The module is built to high – quality standards, ensuring reliable performance in demanding industrial environments. GE offers a comprehensive product guarantee, which includes a standard warranty period. During this time, if the module experiences any manufacturing defects, GE will provide repair or replacement services free of charge. Their global network of technical support teams is available to assist customers with installation, configuration, and troubleshooting. This commitment reflects GE’s confidence in the GE IS230SNCIH6A and its dedication to providing top – notch industrial automation solutions.