Description

Product Overview

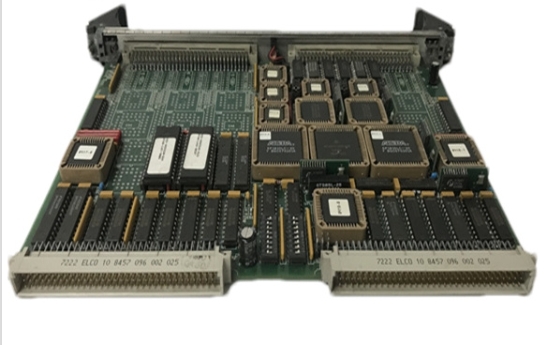

The GE IS210BPPCH1AD is an I/O pack processor board crafted by General Electric, a globally recognized leader in industrial automation and power management. It is an integral part of GE’s Mark VI turbine control system series, which is renowned for its high – performance and reliability in power – generation and industrial – process control applications.

This board is designed to handle the complex tasks of processing and managing input/output signals within the I/O packs that are compatible with the Mark VIe turbine control system. It serves as a crucial link between the control system and the field devices, ensuring seamless data transfer and accurate control. With its advanced processing capabilities, the GE IS210BPPCH1AD can quickly interpret commands from the main control unit and transmit appropriate signals to actuators, sensors, and other components in the turbine control setup. This not only enhances the overall efficiency of the turbine operation but also contributes to better system stability and reliability.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS210BPPCH1AD |

| Manufacturer | GE |

| Product Type | I/O Pack Processor Board |

| Series | Mark VI |

| Assembly Type | 210 Special Assembly |

| Mark VI Series Grouping | Group 1 |

| Mounting Feature | Factory – drilled corners for mounting with standoffs and screw mounts |

| Board Type | Double – sided board using SMT technology |

| Top – side Components | Two Ethernet ports, small inductor/choke, diodes, resistors, capacitors, transistors, multiple integrated circuits, and resistor network arrays |

| Bottom – side Components | Primarily capacitors, resistors, and diodes |

| Operating Temperature Range | [Specify if available, e.g., – 5 °C – 40 °C] |

| Humidity Range | [Specify if available, e.g., a certain relative humidity range] |

Main Features and Advantages

Space – efficient Design

The GE IS210BPPCH1AD utilizes SMT (Surface – Mount Technology) on its double – sided board. This technology allows for a more compact layout, maximizing the use of available space. As a result, it can fit into tight – space I/O pack enclosures without sacrificing functionality. This space – saving design is particularly beneficial in applications where physical space is limited, such as in small – footprint power – generation units or retrofitted industrial control systems.

Ethernet Connectivity

Equipped with two Ethernet ports on the top side, the board enables high – speed and reliable data communication. These Ethernet ports can be used to connect to other components within the control system, such as controllers, switches, and monitoring devices. The high – speed data transfer capabilities of Ethernet ensure that real – time data can be exchanged between the IS210BPPCH1AD and other system elements. This is crucial for applications that require rapid response times, like in the precise control of turbine operations where any delay in data transfer could lead to sub – optimal performance.

Standardized Voltage Management

The hardware components on the IS210BPPCH1AD, including capacitors, resistors, and diodes, are part of a standardized voltage suppression and regulation strategy. This ensures that the board can operate stably under various electrical conditions. By effectively managing voltage fluctuations, it protects the sensitive electronic components on the board from damage due to over – voltage or under – voltage situations. This not only extends the lifespan of the board but also contributes to the overall reliability of the I/O pack and the entire Mark VI turbine control system.

Application Field

Power Generation

In power – generation plants, whether they are gas – fired, steam – powered, or wind – turbine – based, the GE IS210BPPCH1AD plays a vital role. In gas – turbine power plants, it can be used to control the opening and closing of valves that regulate the fuel – air mixture. By accurately processing input signals from sensors that monitor parameters like temperature, pressure, and rotational speed of the turbine, the board can send out control signals to adjust the valve positions. This ensures optimal combustion efficiency, maximizing power output while minimizing fuel consumption and emissions.

Industrial Manufacturing

Industrial manufacturing facilities that use large – scale machinery often rely on turbine – driven power sources. The IS210BPPCH1AD can be used to manage the I/O signals for the control systems of these machines. For example, in a paper – manufacturing plant, the board can control the speed and operation of turbines that drive the large – scale paper – making machinery. It can receive input signals from sensors that detect the tension in the paper web, the temperature of the drying cylinders, and other critical parameters. Based on these inputs, it can send output signals to adjust the speed of the turbines, ensuring consistent paper quality and efficient production.

Oil and Gas Industry

In the oil and gas sector, turbines are used for various applications, such as powering compressors in pipelines and driving pumps in oil – extraction operations. The GE IS210BPPCH1AD can be integrated into the control systems of these turbines. It can monitor and control parameters like the pressure of the gas being compressed or the flow rate of oil being pumped. By providing accurate and timely control signals, it helps maintain the safe and efficient operation of the equipment, reducing the risk of equipment failures and production disruptions.

Related Products

- GE IS210BPPCH1AEC: While similar in function as an I/O – related board, it might have different electrical specifications or be designed for a slightly different subset of applications within the Mark VI system. It could potentially have variations in terms of its processing speed or the type of signals it is optimized to handle compared to the IS210BPPCH1AD.

- GE IS210BPPBH2CAA: This is another process – control – related module in GE’s lineup. It may be designed for more specific industrial – process management tasks, perhaps with a focus on a particular type of industrial process or a different level of control complexity. It could have different communication interfaces or control algorithms compared to the IS210BPPCH1AD.

- GE IS220PPRAH1A: An analog input/output module, it has a different function from the IS210BPPCH1AD which is an I/O pack processor board. The IS220PPRAH1A is mainly concerned with handling analog signals, while the IS210BPPCH1AD focuses on processing and managing I/O signals in the context of the Mark VI turbine control system.

- GE IS200AEPAH1BHC: This could be a related component in terms of being part of the overall control – system infrastructure. It might serve as a supplementary board for power management, communication enhancement, or some other support function that works in tandem with the IS210BPPCH1AD within the Mark VI system.

- GE IS215WEPAH2BB: It may be another board in the Mark VI series, but with different functionality. It could be designed for a different stage of data processing, a different type of I/O handling, or have a different role in the overall system architecture compared to the IS210BPPCH1AD.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS210BPPCH1AD, carefully review the installation manual provided by GE. Ensure that the mounting location is clean, dry, and free from excessive vibrations. Check the power supply to ensure it meets the board’s voltage requirements. Since the board has factory – drilled corners, use appropriate standoffs and screws to securely mount it to the larger circuit board, making sure the screw mounts are properly aligned with the rounded cutouts on the long sides of the board. Also, verify that the Ethernet ports will have proper connectivity to the other components in the system.

Maintenance recommendations: Regularly inspect the IS210BPPCH1AD for any signs of physical damage, such as cracks on the board or loose connections. Check the status of the Ethernet connections to ensure data is flowing correctly. Clean the board periodically to remove dust and debris, as these can affect the performance of the electronic components. Monitor the temperature of the board’s operating environment to ensure it stays within the specified range. If any issues are detected, such as abnormal processing delays or communication errors, refer to the troubleshooting guide in the user manual or contact GE’s technical support for assistance.

Product Guarantee

GE stands firmly behind the quality of the GE IS210BPPCH1AD board. The product undergoes rigorous testing during the manufacturing process to meet high – quality standards. GE offers a standard warranty period, during which any defects in materials or workmanship will be rectified free of charge. Their experienced technical support team is available to assist customers with installation, configuration, and any technical issues that may arise during the product’s lifespan. Whether it’s a problem with the board’s processing capabilities, communication interfaces, or overall functionality, GE is committed to providing timely and effective solutions. This gives customers confidence in their investment and ensures the long – term, reliable operation of the IS210BPPCH1AD in various industrial applications.