Description

Product Overview

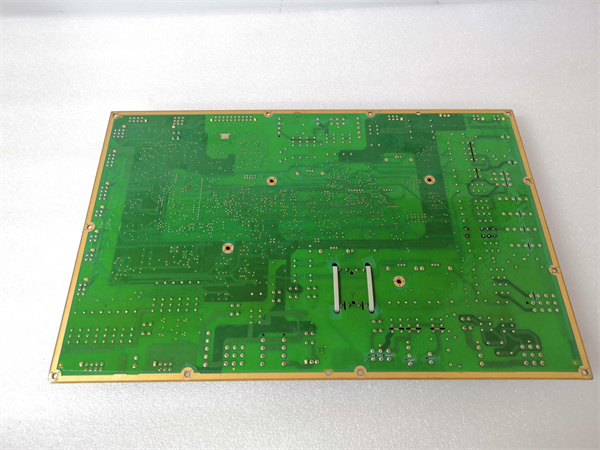

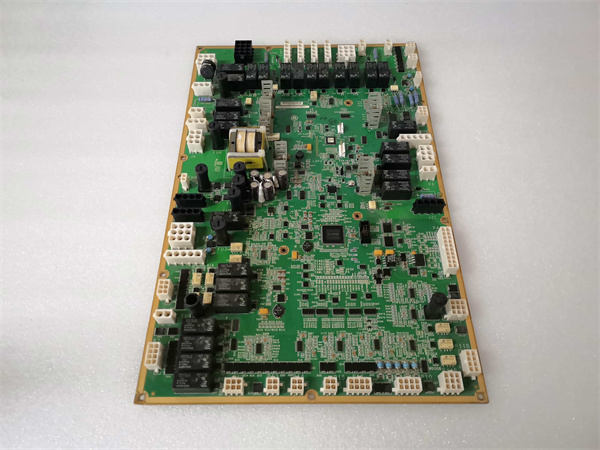

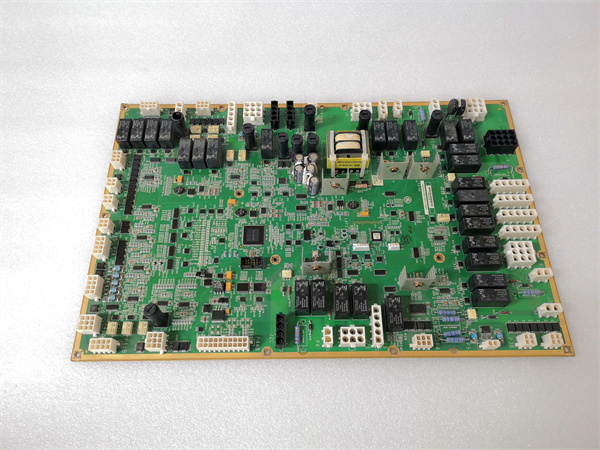

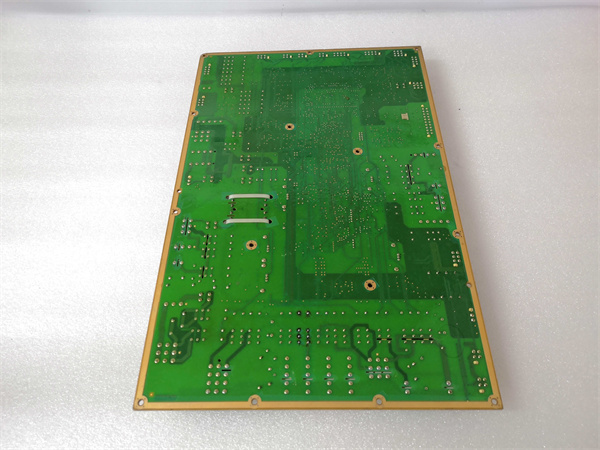

The GE IS200WEMAH1AEA is a printed circuit board (PCB) that plays a pivotal role within the GE Mark VI and Mark VIe control systems. As a key component in these systems, it is engineered to handle the crucial tasks of signal termination, connection, and distribution. This makes it an essential part of industrial automation setups, where seamless communication between different components is of utmost importance. In the context of the overall automation ecosystem, the IS200WEMAH1AEA serves as a reliable interface between the control system and a wide range of external devices such as sensors, actuators, and other peripheral equipment. Its functionality ensures that accurate data is transmitted and received, enabling precise control and monitoring of industrial processes. Whether in large – scale manufacturing plants or power generation facilities, this board contributes to maintaining the stability and efficiency of operations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200WEMAH1AEA |

| Manufacturer | GE |

| Product Type | Printed Circuit Board |

| Signal Types | Analog, Digital, Communication Signals |

| Compatibility | GE Mark VI, Mark VIe Control Systems |

| Operating Temperature Range | – 30°C to 70°C |

| Electromagnetic Compatibility | Complies with Industrial Standards, High Immunity to Interference |

| Mounting Method | Rack Mount or Panel Mount |

| Diagnostic Feature | Real – time Status Detection and Alarm Support |

| Input/Output Channels | Multiple Channels for Input and Output Signals |

| Physical Dimensions | Not Specified (Information Not Available) |

| Weight | Not Specified (Information Not Available) |

IS200WETBH1ABA

Main Features and Advantages

Multichannel Terminal Interface

The GE IS200WEMAH1AEA offers a multi – channel terminal interface, which is highly beneficial for system flexibility. It can support a large number of input and output signals simultaneously. This allows for the connection of numerous sensors and actuators, enabling complex industrial processes to be controlled and monitored comprehensively. For example, in a large – scale manufacturing assembly line, multiple sensors detecting product quality, position, and speed can be connected to the board, along with actuators that control robotic arms and conveyor belts. The board ensures accurate signal transmission and distribution, minimizing data loss or interference, thus guaranteeing the reliability of the entire system.

Modular and Convenient Design

With its modular design, the IS200WEMAH1AEA is compact in size and easy to install. It can be seamlessly integrated with other GE control modules, fitting neatly into existing control cabinets. This modularity also allows for easy expansion of the control system as the industrial process evolves. Additionally, it supports hot – swapping, meaning that the board can be replaced or maintained without shutting down the entire system. In a continuous – operation power plant, this feature is invaluable as it reduces maintenance time and minimizes production downtime, ultimately saving costs.

High Reliability and Stability

Constructed using industrial – grade materials, the GE IS200WEMAH1AEA is built to endure harsh industrial environments. It can withstand high temperatures, mechanical vibrations, and strong electromagnetic interference. In a steel mill, for instance, where there are extreme heat and intense electromagnetic fields, the board continues to function flawlessly. It also features a redundant design, which means that in case of a component failure, there are backup mechanisms in place to ensure the continuous operation of the system. This high – level reliability and stability contribute to the long – term, trouble – free operation of industrial control systems.

IS200WETBH1ABA

Application Field

Energy Control

In the energy sector, the GE IS200WEMAH1AEA is extensively used in power generation equipment such as gas turbines, steam turbines, and water turbines. It is responsible for connecting and transmitting signals related to turbine operation, such as speed, temperature, and pressure sensors. These signals are crucial for controlling the turbines to generate electricity efficiently and safely. In a gas – fired power plant, the board ensures that the turbine operates at optimal conditions by accurately relaying sensor data to the control system, which then adjusts the fuel supply and other parameters accordingly.

Industrial Automation

For industrial automation applications, especially in manufacturing plants, the IS200WEMAH1AEA plays a vital role in signal acquisition and transmission. It connects various sensors on the production line, like proximity sensors on robotic arms or limit switches on conveyor belts, to the control system. This enables the automation system to make real – time decisions based on the sensor data, optimizing the production process. For example, in an automotive manufacturing plant, the board helps in coordinating the movement of different components in the assembly line, ensuring smooth and efficient production.

Oil and Gas

In the oil and gas industry, the board is used to manage the interfaces of sensors and actuators in oil and gas processing equipment. It enables the monitoring and control of processes such as oil extraction, refining, and gas compression. In an oil refinery, sensors detecting the quality and flow rate of crude oil can be connected to the IS200WEMAH1AEA, and the control system can then use this data to adjust the refining process, ensuring the production of high – quality petroleum products.

Related Products

- IS200WETCH1A: Likely part of the same product family, it may have similar functions but could differ in terms of the types of signals it prioritizes or the specific control systems it is more commonly associated with. It might be optimized for different voltage levels or have a different layout of connection points.

- IS200EMIOH1A: This is a thermocouple module by GE. While the IS200WEMAH1AEA focuses on general signal termination and distribution, the IS200EMIOH1A is specialized in handling thermocouple – related signals. They can be used together in a complex industrial control system where both general signal management and temperature measurement via thermocouples are required.

- IS200VCMIH2BEE: It functions as a master communication controller board within the GE industrial gas and steam turbine control system. Unlike the IS200WEMAH1AEA which is more about signal connection at a basic level, the IS200VCMIH2BEE is involved in higher – level communication tasks, such as data transmission via fiber – optic Ethernet. However, they both contribute to the overall operation of the turbine control system.

- IS200AEADH1ABA: Another PCB in the GE product range, it may have different component arrangements and functions. It could be designed for a specific sub – system within the industrial control setup, perhaps with a focus on power management or a particular type of signal processing that complements the signal – distribution function of the IS200WEMAH1AEA.

- IS200EROCH1ABB: This product might be related to the control of certain industrial processes. It could have features that are more process – specific, while the IS200WEMAH1AEA provides a more general – purpose signal – handling platform. They can be integrated in a system where both general signal management and specific process control are needed.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200WEMAH1AEA, it is essential to ensure that the installation area is clean, free from dust, and has proper ventilation. Verify that the power supply to the control system is turned off to avoid any electrical hazards during installation. Familiarize yourself with the wiring diagrams provided in the product manual, as incorrect wiring can lead to malfunctions. Check the compatibility of the IS200WEMAH1AEA with other components in the control system, such as the type of sensors and actuators it will be connected to. Make sure that all the necessary tools, like screwdrivers and wire strippers, are at hand for a smooth installation process.

Maintenance recommendations: Regularly inspect the GE IS200WEMAH1AEA for any signs of physical damage, such as cracks on the PCB or loose connections. Clean the board periodically to remove any accumulated dust, as dust can affect the electrical performance and potentially cause short – circuits. Monitor the temperature of the installation area, as high temperatures can degrade the performance of the board over time. If the board has diagnostic indicators, keep an eye on them for any abnormal readings. In case of any issues, refer to the product manual provided by GE for troubleshooting steps or contact their technical support team.

Maintenance recommendations: Regularly inspect the GE IS200WEMAH1AEA for any signs of physical damage, such as cracks on the PCB or loose connections. Clean the board periodically to remove any accumulated dust, as dust can affect the electrical performance and potentially cause short – circuits. Monitor the temperature of the installation area, as high temperatures can degrade the performance of the board over time. If the board has diagnostic indicators, keep an eye on them for any abnormal readings. In case of any issues, refer to the product manual provided by GE for troubleshooting steps or contact their technical support team.

Product Guarantee

GE stands firmly behind the quality of the GE IS200WEMAH1AEA. The board is covered by a comprehensive quality assurance program. In the event of any manufacturing defects within the specified warranty period, GE will provide free repair or replacement services. Their team of highly skilled technical experts is available around the clock to offer support for installation, operation, and any technical queries related to the IS200WEMAH1AEA. This demonstrates GE’s commitment to ensuring that customers can rely on the product for their critical industrial applications, giving them peace of mind and confidence in the long – term performance of their control systems.