Description

Product Overview

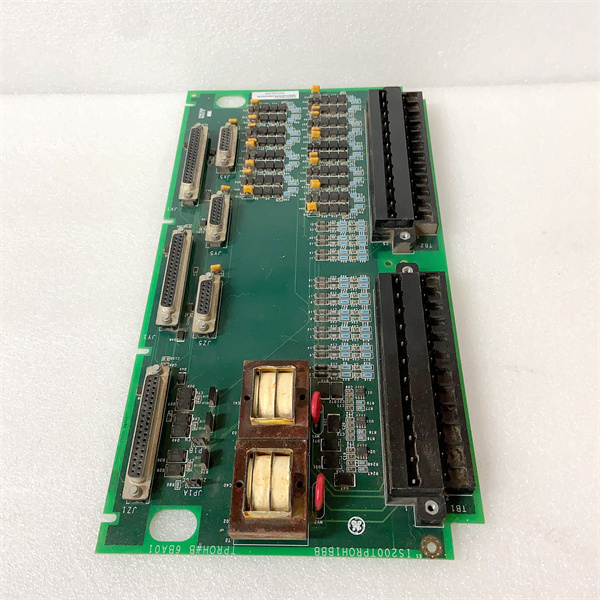

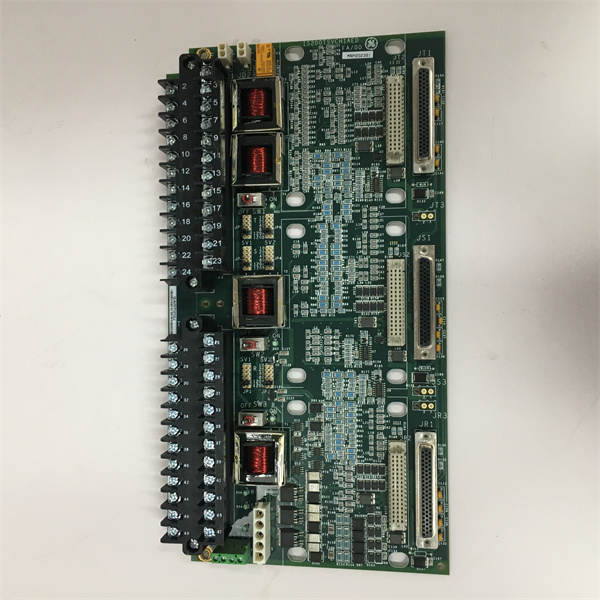

The GE IS200TBCIH2CAA is a high – performance terminal board designed by General Electric for industrial control applications, especially within the Mark VI series of the GE Speedtronic control system. This board is crucial for ensuring seamless communication and data transfer between various components in a control setup. It serves as an interface, allowing for the connection of multiple input and output devices, which is essential for the real – time monitoring and control of industrial processes.

In industrial automation, the GE IS200TBCIH2CAA plays a significant role in maintaining the efficiency and reliability of operations. It can handle different types of signals, be it analog or digital, and translate them into actionable commands for the control system. For example, in a power generation plant, it can interface with sensors that monitor temperature, pressure, and flow rate, and then relay this data to the central control unit. This makes it an integral part of any industrial system that requires precise control and data management.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200TBCIH2CAA |

| Manufacturer | General Electric |

| Product Type | Terminal Board |

| Input Voltage Range | 10 – 30 VDC |

| Output Voltage Range | 10 – 30 VDC |

| Operating Temperature Range | – 40 °C to + 85 °C |

| Communication Interfaces | RS 485, RS232 |

| Number of Channels | 8 |

| Dimensions | 12.5 x 7.5 x 2.5 cm |

| Weight | 0.25 kg |

| Board Type | Control Board |

| Assembly Level | 215 |

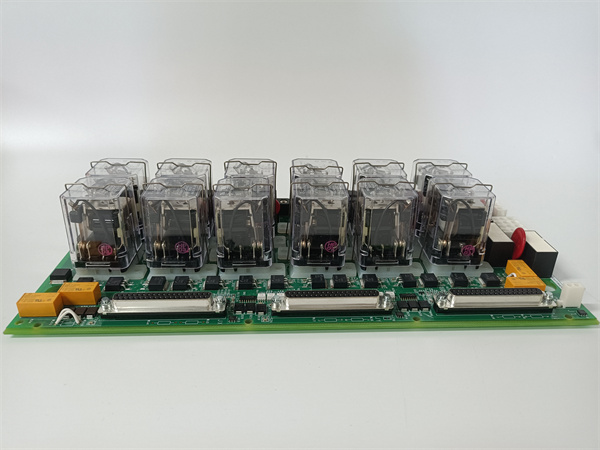

IS200TSVCH1AED

Main Features and Advantages

Robust Communication Capabilities

The GE IS200TBCIH2CAA is equipped with RS 485 and RS232 communication interfaces. These interfaces enable reliable data transfer between different modules in the control system. RS 485, with its multi – drop capability, allows for communication with multiple devices on the same bus, while RS232 provides a simple and direct connection for devices that require point – to – point communication. This versatility in communication protocols makes the board suitable for a wide range of industrial setups.

Wide Temperature Tolerance

With an operating temperature range of – 40 °C to + 85 °C, the GE IS200TBCIH2CAA can function effectively in extreme environmental conditions. This is highly beneficial for industries such as oil and gas, where equipment may be exposed to harsh temperatures both on – shore and off – shore. Whether in the freezing cold of an Arctic oil rig or the sweltering heat of a desert – based refinery, this board can maintain its performance, ensuring continuous operation of the control system.

Compact Design

Measuring 12.5 x 7.5 x 2.5 cm and weighing only 0.25 kg, the GE IS200TBCIH2CAA has a compact form factor. This makes it easy to install in control cabinets with limited space. Its small size does not compromise its functionality, as it can still handle multiple channels and complex communication tasks. The compact design also simplifies system integration, as it can be added to existing setups without requiring major modifications to the cabinet layout.

IS200TSVCH2AED MRP246517

Application Field

Power Generation

In power plants, be it coal – fired, gas – fired, or hydroelectric, the GE IS200TBCIH2CAA is used to interface with various sensors and actuators. It can connect to temperature sensors in the boiler, pressure sensors in the steam lines, and flow meters in the water or fuel supply systems. The data from these sensors is then transmitted to the main control system, allowing operators to monitor and adjust the power generation process for optimal efficiency. For example, it can help in regulating the fuel – air mixture in a gas – fired turbine to ensure clean and efficient combustion.

Manufacturing

Manufacturing plants rely on precise control systems to ensure product quality and production efficiency. The GE IS200TBCIH2CAA is used to connect different parts of the production line. It can interface with motors, conveyors, and robotic arms, sending and receiving control signals. In a car manufacturing plant, for instance, it can control the movement of conveyor belts that transport car parts to different assembly stations, and also receive feedback from sensors that detect the position and orientation of the parts, ensuring accurate assembly.

Oil and Gas

In the oil and gas industry, the GE IS200TBCIH2CAA is deployed in refineries, pipelines, and offshore platforms. It can connect to sensors that monitor the level of oil or gas in storage tanks, the pressure in pipelines, and the flow rate of fluids. This data is crucial for maintaining the safety and efficiency of operations. In an offshore platform, it can be used to control the opening and closing of valves based on the pressure and flow rate readings, preventing leaks and ensuring smooth production.

Related Products

GE IS200TVBAH2ACC: This is a vibration input terminal board from GE, similar to the GE IS200TBCIH2CAA in terms of being part of the Mark VI series. However, while the GE IS200TBCIH2CAA focuses on general communication and interface functions, the IS200TVBAH2ACC is specialized in converting turbine vibration sensor signals for processing.

GE IS200TDBSH2AAA: Another board in the GE family. It may have different input and output specifications compared to the GE IS200TBCIH2CAA. For example, it could be designed to handle higher voltage or current levels, or have a different number of channels for specific industrial applications.

GE Mark VI Controllers: These controllers work in tandem with the GE IS200TBCIH2CAA. The controllers process the data received through the GE IS200TBCIH2CAA from various sensors and devices, and then send out control commands back through the same or other related boards to actuators, thus controlling the overall industrial process.

GE PAC8000 I/O Modules: These modules can be connected to the GE IS200TBCIH2CAA to expand the input and output capabilities of the control system. They may offer additional analog or digital input/output channels, allowing for more comprehensive monitoring and control of industrial processes.

GE 8920 – PS – DC: This is a power supply module. The GE IS200TBCIH2CAA relies on a stable power source like the GE 8920 – PS – DC to function properly. The power supply module provides the necessary electrical power to the GE IS200TBCIH2CAA, ensuring it can perform its communication and interface functions without interruption.

GE IS200TDBSH2AAA: Another board in the GE family. It may have different input and output specifications compared to the GE IS200TBCIH2CAA. For example, it could be designed to handle higher voltage or current levels, or have a different number of channels for specific industrial applications.

GE Mark VI Controllers: These controllers work in tandem with the GE IS200TBCIH2CAA. The controllers process the data received through the GE IS200TBCIH2CAA from various sensors and devices, and then send out control commands back through the same or other related boards to actuators, thus controlling the overall industrial process.

GE PAC8000 I/O Modules: These modules can be connected to the GE IS200TBCIH2CAA to expand the input and output capabilities of the control system. They may offer additional analog or digital input/output channels, allowing for more comprehensive monitoring and control of industrial processes.

GE 8920 – PS – DC: This is a power supply module. The GE IS200TBCIH2CAA relies on a stable power source like the GE 8920 – PS – DC to function properly. The power supply module provides the necessary electrical power to the GE IS200TBCIH2CAA, ensuring it can perform its communication and interface functions without interruption.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200TBCIH2CAA, first, verify that the input voltage of the power source lies within the specified 10 – 30 VDC range. Ensure the installation area is clean, free from dust, and has proper ventilation to prevent overheating. Check the physical condition of the board for any signs of damage during transit. Follow the installation manual provided by GE carefully, which will guide you on how to correctly connect the communication cables (RS 485 and RS232) and other necessary wiring. Make sure to properly ground the board to avoid electrical interference.

Maintenance recommendations: Regularly inspect the GE IS200TBCIH2CAA for any loose connections. Over time, vibrations in industrial environments can cause connectors to become loose, which may disrupt communication. Clean the board periodically to remove dust that could potentially affect its performance. Monitor the temperature of the installation area to ensure it remains within the – 40 °C to + 85 °C operating range. If any issues arise, such as communication failures or incorrect data transfer, refer to the troubleshooting guide in the product manual. In case of severe damage or malfunction, contact GE’s technical support for further assistance.

Product Guarantee

General Electric offers a comprehensive product guarantee for the GE IS200TBCIH2CAA. The board undergoes rigorous testing during the manufacturing process to ensure it meets high – quality standards. GE provides a standard warranty period, during which, if the board shows any manufacturing defects, they will offer repair or replacement services free of charge. Their team of experienced technical experts is available to offer support for installation, operation, and troubleshooting. This commitment to quality and customer service reflects GE’s confidence in the reliability and durability of the GE IS200TBCIH2CAA, giving customers peace of mind when using this board in their industrial control systems.