Description

Product Overview

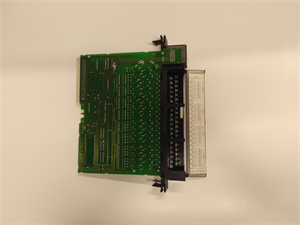

The GE IC697MDL653 is a discrete input module designed for the GE Fanuc Series 90 – 70 programmable logic controllers (PLCs). It plays a pivotal role in industrial automation systems by accurately detecting and relaying digital input signals. With its 32 discrete input channels, grouped into four sets of eight, it offers high – density input capabilities. This makes it suitable for applications where numerous digital signals from various sensors, switches, and other input devices need to be monitored.

The IC697MDL653 is engineered to operate with a 24 VDC power supply, providing stable and reliable operation. Its positive/negative logic compatibility allows for greater flexibility in connecting different types of input devices, such as pushbuttons, limit switches, and proximity sensors. This adaptability ensures seamless integration within diverse industrial setups, enhancing the overall functionality and efficiency of the control system. Whether in a manufacturing plant, a power generation facility, or a water treatment plant, the GE IC697MDL653 module serves as a key component for data acquisition and control, enabling smooth operation of industrial processes.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697MDL653 |

| Manufacturer | General Electric |

| Product Type | Discrete Input Module |

| Rated Voltage | 24 VDC |

| Input Voltage Range | – 3 to +30 VDC |

| Number of Inputs | 32 (4 groups of 8 each) |

| Input Current | 10 mA at rated voltage |

| Input Impedance | 2.6 KΩ (typical) |

| Isolation Voltage | 1500 volts (any input to backplane), 500 volts (between input groups) |

| Filter Delay Time | 1 ms or 10 ms (configurable) |

| Current Required from 5V Bus | 0.3 A |

| Compatible with | GE Fanuc Series 90 – 70 PLCs |

| Input Devices Compatibility | Pushbuttons, limit switches, selector switches, 2 – wire and 3 – wire electronic proximity switches |

| Mechanical Keying | Yes, to ensure correct installation |

IC697MDL653

Main Features and Advantages

High – Density Input

The GE IC697MDL653 offers 32 input channels, which is highly beneficial for applications that require monitoring of a large number of digital signals. In a large – scale manufacturing plant, for example, it can be used to monitor the status of numerous sensors and switches spread across different production lines, reducing the need for multiple smaller – capacity input modules and simplifying the overall system architecture.

Positive/Negative Logic Compatibility

This module’s ability to support both positive and negative logic is a significant advantage. It can interface with a wide variety of input devices, regardless of their logic configuration. For instance, it can be easily connected to both sinking and sourcing sensors, providing flexibility in system design and making it adaptable to different industrial setups without the need for complex logic – conversion circuits.

Configurable Input Filter

The selectable input filter with a delay time of 1 ms or 10 ms helps in reducing electrical noise interference. In industrial environments where electrical noise is prevalent, such as near motors or high – voltage equipment, the filter can be configured to ensure that only clean and reliable input signals are received by the PLC. This improves the accuracy and stability of the control system, minimizing false triggering due to noise.

Interrupt Capability

One of the module’s inputs can be configured as an interrupt. In applications where certain events require immediate attention, such as emergency stop signals or critical sensor alarms, the interrupt function allows the PLC to quickly respond. This feature is crucial for ensuring the safety and efficient operation of industrial processes, as it enables the system to prioritize and act on critical events without delay.

Application Field

In manufacturing industries, the GE IC697MDL653 is extensively used. For example, in an automotive assembly line, it can monitor the status of limit switches on robotic arms to ensure they are in the correct position during part – handling operations. It can also detect the presence of components on conveyor belts through proximity sensors, enabling seamless coordination of the assembly process.

Power generation plants also rely on this module. It can monitor the status of various switches and sensors in the power generation equipment, such as the position of circuit breakers, the status of cooling fans, and the operation of pumps. This helps in ensuring the stable and efficient operation of the power plant, allowing for quick detection and response to any abnormal conditions.

In building automation systems, the IC697MDL653 can be used to monitor the status of door sensors, window sensors, and occupancy detectors. This data can then be used to control lighting, HVAC systems, and security systems, optimizing energy consumption and enhancing the comfort and security of building occupants.

IC697MDL653

Related Products

- GE IC697MDL240: A discrete input module with different input characteristics. It may have fewer input channels compared to the IC697MDL653, making it suitable for applications with less input requirements.

- GE IC697MDL750: Another discrete output module in the same series. While the IC697MDL653 focuses on input functions, the IC697MDL750 is designed to provide output signals to control external devices, and they often work in tandem within a PLC – based control system.

- GE IC697CMM721: A communication module that can be used in conjunction with the IC697MDL653. It enables the transfer of data collected by the input module to other components in the industrial automation system, such as HMIs or other control units, facilitating system – wide communication and control.

- GE IC696CPU310: A CPU module that pairs with the IC697MDL653. The CPU processes the input data received from the IC697MDL653 module according to the programmed control logic, making it an essential component for overall system operation.

- GE IC697MDL645: A discrete input module similar to the IC697MDL653, but it may have different voltage ratings or isolation features. It can be an alternative choice depending on the specific requirements of the industrial application, such as in environments with different electrical characteristics.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC697MDL653, ensure that the power to the PLC system is turned off to avoid electrical hazards. Check the module for any visible damage during transportation. Verify that the installation location meets the environmental requirements in terms of temperature, humidity, and electromagnetic interference. Familiarize yourself with the wiring diagram and make sure you have the appropriate wire gauges (AWG #22 to AWG #14) for connection. Ensure that the PLC system is compatible with the IC697MDL653 module, especially in terms of software configuration and communication protocols.

Maintenance recommendations: Regularly inspect the IC697MDL653 for any signs of overheating, such as discoloration or abnormal heat. Check the LED indicators on the module to monitor the status of input channels. Periodically clean the module to remove dust and debris, as these can affect its performance. If any input channels show abnormal behavior, check the wiring connections first. If the problem persists, consider replacing the module. Keep the module’s software up – to – date by following the manufacturer’s instructions for firmware updates, as this can improve performance and fix any known bugs.

Product Guarantee

GE stands firmly behind the quality of the GE IC697MDL653. The company employs strict quality – control measures during the manufacturing process to ensure that each module meets high – industry standards. In case of any manufacturing defects within the warranty period, GE offers comprehensive after – sales service. This includes free repair or replacement of the module, along with technical support from its team of experts. GE’s global network of support centers is available to assist customers promptly, providing solutions to any issues related to the IC697MDL653. Whether it’s installation – related queries, troubleshooting, or advice on system integration, customers can rely on GE’s expertise. This commitment not only reflects GE’s confidence in the reliability and performance of the IC697MDL653 but also ensures that industrial customers can operate their automation systems with peace of mind.