Description

Product Overview

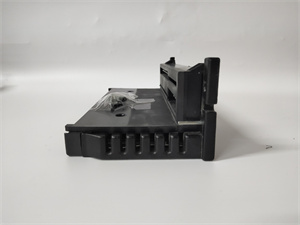

The GE IC660TBA026 is an analog output module of great significance within the industrial automation landscape, especially as part of GE Fanuc’s Genius I/O series. This module is designed to be a reliable source for providing analog output signals in various industrial control systems.

Its core function is to generate and output analog signals with a signal rating in the range of 4 to 20 milliamps. This makes it highly suitable for applications where precise control of analog – based devices is required. With 6 inputs, it can efficiently handle multiple input signals and convert them into the appropriate output signals. The GE IC660TBA026 is engineered to interface seamlessly with other components in an industrial setup, whether it’s being controlled by an IBM PC, PLC, or other programmable logic controllers. It plays a crucial role in ensuring the smooth operation of industrial processes by accurately transmitting analog control signals to actuators, valves, and other end – devices, thus enhancing the overall efficiency and precision of industrial automation systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC660TBA026 |

| Manufacturer | GE |

| Product Type | Analog Output Module |

| Series | Genius I/O |

| Input Voltage Rating | 115 VAC and 125 VDC |

| Number of Inputs | 6 |

| Signal Rating | 4 – 20 mA |

| Output Accuracy at 25 °C | 0.15% |

| Operating Temperature | 0 – 60 °C |

| Storage Temperature | – 40 – 100 °C |

| Dimensions (H x D x W) | 8.83 in x 3.94 in x 3.50 in |

| Heat Dissipation | 12 W |

| Monitor Port | Available on front panel |

| Serial Ports | Serial Port 1 and Serial Port 2 |

| Shielded Ports | Shielded input and output ports |

IC660TBA026

Main Features and Advantages

Precise Signal Output

The GE IC660TBA026 offers a high – level of output accuracy, with a 0.15% accuracy at 25 °C. This precision is crucial for applications where even the slightest deviation in analog signals can lead to sub – optimal performance or errors in the controlled process. Whether it’s controlling the flow rate of a chemical in a manufacturing process or the speed of a motor in a production line, the accurate 4 – 20 mA output ensures reliable and consistent operation.

Multiple Input Handling

Featuring 6 inputs, the module can manage multiple input signals simultaneously. This multi – input capability allows for greater flexibility in industrial setups, as it can interface with a variety of sensors or control signals. It can aggregate and process these inputs to generate the appropriate analog output, enabling more complex control strategies.

Enhanced Diagnostic Capabilities

This module comes equipped with enhanced diagnostic functions. It can detect over – range and under – range conditions in the output, and when the output feedback drops below 1.5 mA, it can alert the operator. This early – warning system helps in preventing equipment failures and maintaining the integrity of the industrial process. By quickly identifying potential issues, it minimizes downtime and reduces maintenance costs.

Compact Design

The IC660TBA026 has a compact size, measuring 8.83 inches in height, 3.94 inches in depth, and 3.50 inches in width. This compact design makes it easy to install in various control panels, saving valuable space. In industrial environments where space may be limited, this feature allows for more efficient use of the available area, while still providing powerful analog output functionality.

IC660TBA026

Application Field

Manufacturing Industry

In manufacturing, the GE IC660TBA026 is widely used to control the operation of various machinery. For example, in a plastics manufacturing plant, it can be used to control the speed of extruders by sending precise analog signals. By adjusting the speed based on different production requirements, it ensures consistent product quality. In an automotive assembly line, it can control the movement of robotic arms by regulating the voltage or current supplied to their motors, ensuring accurate and smooth movements during the assembly process.

Process Control in Chemical Plants

Chemical plants rely heavily on precise control of processes. The IC660TBA026 can be used to control the flow of chemicals in pipelines. By sending analog signals to control valves, it can accurately regulate the amount of chemicals flowing into reactors, ensuring the proper chemical reactions occur. This helps in maintaining product quality, preventing waste, and ensuring the safety of the overall process.

Power Generation

In power generation facilities, the module plays a role in controlling the operation of turbines. It can adjust the position of turbine blades by sending analog signals to hydraulic actuators. This adjustment helps in optimizing the efficiency of power generation, ensuring that the turbines operate at their peak performance levels under different load conditions.

Related Products

- GE IC660TBA023: A terminal assembly by GE Fanuc with 16 circuits. It serves as a connection point for electrical circuits in industrial setups, while the IC660TBA026 focuses on analog output functions.

- GE IC660TBA024: An input/output block using a current power source. It has a combination of input and output capabilities, differing from the pure analog output function of the IC660TBA026.

- GE IC660TBA025: Also a current – source analog output block, similar to IC660TBA026, but may have different specifications or features, such as differences in the number of inputs or output accuracy.

- GE IC660TBA101: A terminal assembly that monitors temperature inputs from temperature detectors. It has a different application focus compared to the IC660TBA026 which is mainly for analog output control.

- GE IC660TBA103: A genius terminal assembly with a rated voltage of 115 volts AC and 125 volts DC, used in thermocouple applications, distinct from the IC660TBA026‘s analog output functionality.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC660TBA026, carefully check the input voltage source to ensure it meets the module’s requirements of 115 VAC or 125 VDC. Thoroughly read the installation manual to understand the correct mounting method and wiring connections. Make sure the installation area has a suitable temperature range between 0 – 60 °C. Prepare all the necessary tools such as screwdrivers and wire strippers. Also, ensure that the surrounding environment is free from excessive dust, moisture, and electromagnetic interference, which could affect the module’s performance.

Maintenance recommendations: Regularly inspect the IC660TBA026 for any signs of physical damage, such as cracks on the casing or loose connections. Monitor the output signals to ensure they are within the expected 4 – 20 mA range. Clean the module periodically to remove any dust or debris that may have accumulated, as this can impact its performance. If any abnormal behavior is detected, such as incorrect output values or diagnostic alerts, refer to the troubleshooting guide in the user manual. Periodically check the monitor port and serial ports for any signs of malfunction, and ensure that the module’s heat dissipation remains normal to prevent overheating issues.

Product Guarantee

GE stands firmly behind the quality of the GE IC660TBA026 module. The product undergoes rigorous testing during the manufacturing process to meet high – quality standards. GE offers a standard warranty period, during which any defects in materials or workmanship will be rectified free of charge. Their experienced technical support team is available to assist customers with installation, configuration, and any technical issues that may arise during the product’s lifespan. Whether it’s a problem with signal accuracy, input handling, or module functionality, GE is committed to providing timely and effective solutions. This not only gives customers confidence in their investment but also ensures the long – term, reliable operation of the IC660TBA026 in industrial applications.