Description

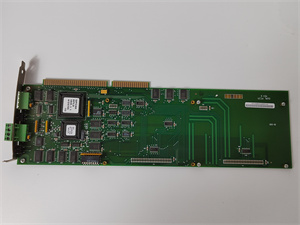

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC660BBD025 |

| Manufacturer | GE |

| Product Type | Digital I/O Module |

| Input Voltage Range | 4.9 – 5.3 VDC (for 5 V nominal), 10 – 30 VDC (for 12/24 V nominal) |

| Load Current per Circuit | 0.5 A |

| Inrush Current | 4 A (up to 10 ms) |

| Total Output Current Capacity | 16 A |

| Isolation Voltage (Block – to – Block) | 850 V |

| Number of Channels | 32 |

| Input Signal Processing Time | 1.4 ms |

| Optional Filter Time | 1 – 100 ms |

| Heat Dissipation | 11 W with 8 inputs active, 18 W with 32 inputs active |

| Operating Temperature | 0 °C – 60 °C |

| Storage Temperature | – 40 °C – 100 °C |

| Humidity | 5% – 95% (non – condensing) |

| Dimensions (H x W x D) | 22.4 cm x 9.1 cm x 11.9 cm |

| Weight | Approximately 1.8 kg |

IC660ELB921M

Main Features and Advantages

Flexible Configuration: The 32 – circuit design of the GE IC660BBD025 allows for extensive configurability. These circuits can be set up as inputs, outputs, or outputs with feedback. For example, in a manufacturing assembly line, some circuits can be configured to receive signals from sensors that detect the presence of components, while others can be used to control the actuators that move and assemble those components. This flexibility enables it to be tailored precisely to the unique requirements of different industrial processes.

High – Speed Signal Processing: With a rapid input signal processing time of 1.4 ms, the module can quickly respond to changes in the industrial environment. In high – speed production lines, such as those in the automotive or electronics industries, this quick response time ensures that the control system can make timely decisions. The optional filter time, ranging from 1 – 100 ms, helps to eliminate electrical noise and interference, ensuring the accuracy of the input signals.

Robust Diagnostic and Protection: The module comes equipped with advanced diagnostic features. LED indicators for unit and I/O status provide real – time visual feedback on the module’s operation. It can detect switch failures and has self – protection mechanisms against overloads, short – circuits, and overheating. In harsh industrial settings, these protection features safeguard the module and connected devices, reducing the risk of damage and system downtime.

Reliable Communication: The GE IC660BBD025 supports the Genius communication protocol. This enables seamless integration with other GE PLCs, DCS systems, and Genius – compatible devices. In large – scale industrial complexes, it can communicate effectively with various components across the automation network, ensuring smooth data flow and coordinated control.

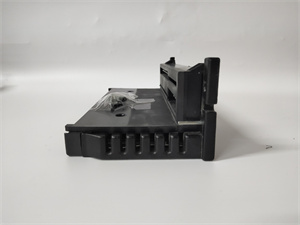

IC660TBA026

Application Field

Power Generation: In power plants, whether they are thermal, hydro, or wind – powered, this module plays a crucial role. In a thermal power plant, it can be used to monitor and control the opening and closing of valves. Input signals from pressure sensors can be received by the module, and it can then send output signals to control the actuators that operate the valves. In a wind power plant, it can control the pitch and yaw of wind turbine blades. Inputs from wind direction and speed sensors are processed, and the module sends commands to adjust the blade angles for optimal energy capture.

Industrial Automation in General: In any industrial setting where automation is implemented, the GE IC660BBD025 is a valuable asset. In a packaging industry, it can control the operation of packaging machinery, ensuring accurate filling, sealing, and labeling. In a chemical plant, it can be used to control the flow of chemicals by monitoring sensors and controlling valves. Its ability to handle digital signals effectively makes it suitable for a wide range of industrial applications, improving the overall efficiency and reliability of industrial processes.

Related Products

GE IC660TBD025: It belongs to the same Genius I/O series. Although details about its differences are scarce, it likely has variations in terms of circuit configuration, signal handling capabilities, or physical form factor, making it suitable for different industrial applications compared to the GE IC660BBD025.

GE IC660EBD025: Another module in the series, it may have enhanced features such as more advanced communication capabilities or additional diagnostic functions. It could be designed for applications that require higher – level monitoring and control within the industrial automation system.

GE PLC Controllers: These controllers work in tandem with the GE IC660BBD025. The PLC controllers execute the control logic based on the input signals received by the IC660BBD025 module and send output commands back to it for controlling field devices.

GE Industrial Sensors: Sensors like proximity sensors, pressure sensors, and temperature sensors can be connected to the GE IC660BBD025. Different types of sensors provide various input signals related to the industrial process, which the module then processes and relays to the control system.

Installation and Maintenance

Maintenance recommendations: Regularly monitor the GE IC660BBD025 using the LED indicators. Check for any abnormal status lights, which could indicate issues such as input or output failures. Clean the module periodically to remove dust and debris, especially in dusty industrial environments, as these can affect the module’s performance. If any problems occur, refer to the product manual for troubleshooting steps. In case of component failures, replace the faulty parts with genuine GE – approved components to maintain the module’s performance and reliability.