Description

Detailed parameter table

|

Parameter name

|

Parameter value

|

|

Product model

|

CC – TDOB01

|

|

Manufacturer

|

Honeywell

|

|

Product category

|

Digital Output Module

|

|

Electrical performance

|

Operating voltage: 24V DC; On – sense voltage/current: 18 – 30V DC, 13V DC (min) or 3 mA (min); Off – sense voltage/current: 5V DC (max) or 1.2 mA (max); Input impedance: 4.2 kΩ

|

|

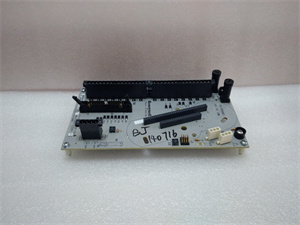

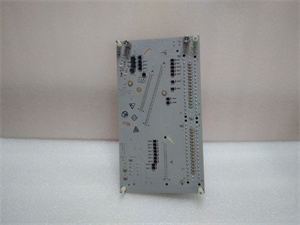

Physical size

|

Weight: approximately 0.5 – 0.55 kg; Dimension: 16 * 6 * 3 (cm)

|

|

Interface type

|

Connection points for field device connection

|

|

Communication protocol

|

Not prominently specified in main sources, but interfaces with relevant control systems for data transfer

|

|

Environmental requirements

|

Operating temperature range: – 20 °C to + 60 °C; Humidity: 5% – 95% non – condensing; Protection level: IP20

|

|

Installation method

|

DIN – rail mounted

|

|

Performance indicators

|

Output channels: typically 4, 8, or 32; Galvanic isolation (any input terminal voltage referenced to common): 1500 VAC rms or ± 1500 VDC; Isolation technique: optical; Field – configurable outputs; Latched, pulsed or pulse – width modulated output (per channel); “Fuse – less” short circuit protection; Extensive diagnostics; Optional redundancy; Safe – state (failopt) behaviors

|

|

Current draw

|

Not specified in some sources, but for similar modules may be relevant to power requirements

|

|

Heat dissipation

|

Not specified in main sources

|

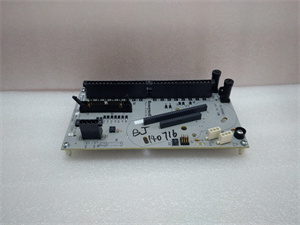

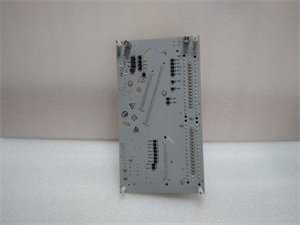

Honeywell CC-TDOB01

Product introduction

The Honeywell CC – TDOB01 is a high – performance digital output module, purpose – built for industrial automation applications. As an integral part of Honeywell’s comprehensive industrial control product portfolio, it serves a critical function in translating digital signals from PLCs or controllers into switch – type signals. This conversion enables the seamless control of actuators like relays, motors, and other industrial devices, thereby automating industrial processes.

The CC – TDOB01 is designed to be highly adaptable within industrial control systems. It can be integrated into various distributed control systems (DCS), such as those in the Experion series C I/O system. In the context of an industrial plant, this module acts as the bridge between the control center and the field – level devices. By accurately outputting digital signals, it allows for the precise operation of machinery, ensuring smooth production flow and efficient process control. Whether in a manufacturing facility with complex production lines or an energy – production plant with strict control requirements, the Honeywell CC – TDOB01 plays a vital role in making industrial automation a reality.

Core advantages and technical highlights

High – density and flexible output channels

The CC – TDOB01 offers multiple output channels, with options typically including 4, 8, or 32 channels. This high – density design allows for the connection and control of a large number of field devices simultaneously. In a large – scale manufacturing plant, for example, the module can be used to control numerous relays and motors across different production lines. Additionally, the field – configurable outputs provide users with the flexibility to adjust the output settings according to specific application needs. This means that the module can be tailored to different industrial scenarios, whether it’s a simple on – off control application or a more complex system requiring specific output patterns.

Robust isolation and protection features

Featuring optical isolation between input and output channels, the CC – TDOB01 effectively shields against electrical interference. This isolation is crucial in industrial environments, where electromagnetic interference can be a common issue. The module also comes with “fuse – less” short – circuit protection, which safeguards the module and connected devices from damage in case of short – circuits. In hazardous industrial settings, such as chemical plants, this protection feature is essential for maintaining safe and continuous operation. Moreover, the extensive diagnostics capabilities of the CC – TDOB01 enable quick identification of any faults or malfunctions, reducing downtime and improving overall system reliability.

Durable and reliable construction

Built to withstand harsh industrial conditions, the CC – TDOB01 can operate within a wide temperature range of – 20 °C to + 60 °C and a humidity range of 5% – 95% non – condensing. Its robust construction ensures long – term reliability, even in challenging environments like steel mills or mines. The module is designed to be easily installed on DIN rails, simplifying the installation process and reducing the time and effort required for system setup. With optional redundancy features, the CC – TDOB01 can be configured to provide backup in case of primary module failure, further enhancing the reliability of the industrial control system.

Honeywell CC-TDOB01

Typical application scenarios

Manufacturing industry

In manufacturing plants, the Honeywell CC – TDOB01 is extensively used to control a variety of equipment. On an automotive assembly line, it can be used to control the operation of robotic arms, conveyor belts, and other automated machinery. For example, the module can send digital output signals to activate relays that control the movement of robotic arms, ensuring precise and coordinated assembly operations. In a food and beverage manufacturing facility, the CC – TDOB01 can be used to control the filling and packaging machines. By accurately controlling the opening and closing of valves and the operation of motors, it ensures consistent product quality and high production efficiency.

Energy sector

In power generation plants, whether they are thermal, hydro, or renewable energy – based, the CC – TDOB01 plays a crucial role. In a thermal power plant, it can be used to control the operation of pumps, fans, and other auxiliary equipment. For instance, the module can send signals to start or stop pumps that supply cooling water to the turbines, ensuring the efficient operation of the power – generation process. In a wind farm, the CC – TDOB01 can be used to control the yaw and pitch mechanisms of wind turbines. By accurately controlling these mechanisms, the turbines can be adjusted to optimize energy capture, improving the overall efficiency of the wind farm.

Process control in chemical and petrochemical industries

In chemical and petrochemical plants, the CC – TDOB01 is used for precise process control. It can be used to control the opening and closing of valves in chemical reactors, ensuring the proper flow of reactants and products. In a petrochemical refinery, the module can be used to control the operation of distillation columns. By controlling the motors that drive the pumps and agitators in the distillation process, it helps to maintain the correct temperature, pressure, and flow rates, ensuring the production of high – quality petrochemical products.

Related model recommendations

- CC – TDOB11: Likely a more advanced or redundant version of the CC – TDOB01. While the CC – TDOB01 offers standard digital output functionality, the CC – TDOB11 may provide enhanced features such as additional redundancy options or improved diagnostic capabilities. In applications where system reliability is of utmost importance, such as in safety – critical industrial processes, the CC – TDOB11 could be a better choice.

- CC – PDOB01: Another digital output module from Honeywell. It may have different characteristics in terms of output channel configuration, voltage handling, or response times. Depending on the specific requirements of the industrial control system, either the CC – TDOB01 or the CC – PDOB01 could be selected. For example, if the application requires a different number of output channels or has specific voltage – compatibility needs, one module may be more suitable than the other.

- CC – TDIL01: A digital input module that can work in tandem with the CC – TDOB01 in a complete industrial control system. The CC – TDIL01 is responsible for reading digital input signals from field devices, and the CC – TDOB01 can be used to output digital control signals based on the processed input data. In an industrial process where digital signals are used for both sensing and control, these two modules can be integrated to form a comprehensive input – output solution.

- CC – TAON01: This may be an analog output module. In industrial systems where both analog and digital output capabilities are required, the CC – TDOB01 can handle the digital output tasks, while the CC – TAON01 can be used for analog output applications. For example, in a control system that needs to control both digital relays and analog – controlled valves, these two modules can work together to meet the diverse output requirements.

- CC – PAIM01: It could be involved in more complex control functions, perhaps related to process control algorithms. The CC – TDOB01 provides the basic digital output functionality, and the CC – PAIM01 can use the output data from the CC – TDOB01 to perform advanced control operations. In an industrial process control system, they can collaborate to achieve more sophisticated control strategies, with the CC – TDOB01 as the means of outputting control signals and the CC – PAIM01 for processing and decision – making based on the overall system requirements.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell CC – TDOB01, select a clean, dry location within the control cabinet. Ensure that the ambient temperature is within the specified range of – 20 °C to + 60 °C. Gather the necessary tools, which typically include screwdrivers for mounting the module on the DIN rail. Carefully inspect the CC – TDOB01 for any signs of damage during transportation. When making the electrical connections, follow the wiring diagrams provided in the product documentation precisely. Connect the 24V DC power supply correctly, paying strict attention to the polarity. All connections to field devices should be made securely to prevent loose connections that could lead to signal interference or incorrect output.

Maintenance suggestions

Regularly check the physical condition of the CC – TDOB01 for any signs of wear, corrosion, or loose connections. Monitor the power supply voltage to ensure it remains stable at 24V DC. Periodically verify the output signals to confirm they are operating as expected. In case of any abnormal behavior, such as incorrect output or communication issues, refer to the troubleshooting guide in the product manual. If a component needs replacement, use only genuine Honeywell spare parts to maintain the integrity and performance of the module. Keep the control cabinet clean and free of dust, as dust accumulation can affect the module’s performance over time, especially in dusty industrial environments. Additionally, take advantage of the module’s diagnostic features to proactively identify and address potential issues before they cause system failures.

Service and guarantee commitment

Honeywell stands firmly behind the CC – TDOB01 with a comprehensive service and guarantee commitment. The module comes with a standard warranty that safeguards against defects in materials and workmanship. Honeywell’s global network of technical support teams is available around the clock. Whether it’s assistance during the installation phase, help with commissioning the module, or troubleshooting complex issues, these experts are readily accessible. The company also provides regular software updates and product enhancements to ensure that the CC – TDOB01 continues to perform optimally in evolving industrial environments. This commitment to service and quality assurance reflects Honeywell’s confidence in the reliability and durability of the CC – TDOB01, giving customers peace of mind when integrating it into their critical industrial control systems.