Description

1. Product Description

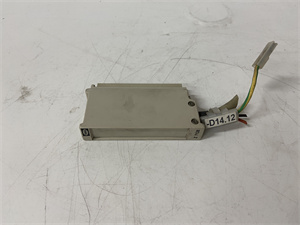

The HIMA Z7128 is a high-performance safety-related input/output (I/O) module designed to deliver precise and reliable signal processing in industrial safety instrumented systems (SIS). As a key component of HIMA’s modular automation portfolio, the Z7128 is engineered to interface with sensors, actuators, and other field devices, enabling seamless integration into safety-critical control environments. Built with robust fault-detection capabilities, this module ensures accurate data transmission and system integrity, making it an essential choice for industries that demand compliance with international safety standards.

The HIMA Z7128 supports both digital and analog signals, allowing it to handle a wide range of input/output tasks, from monitoring process variables to triggering safety actions. Its compact design and modular architecture facilitate easy installation and maintenance, while its high-speed communication ensures real-time data exchange with control systems. Whether used in emergency shutdown systems, fire and gas detection, or critical process control, the Z7128 provides the reliability and precision required for mission-critical applications.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | 24 V DC ±15% |

| Signal Types | Digital inputs/outputs (8 channels per module) |

| Voltage Range (Input) | 11–30 V DC (for digital inputs) |

| Current Capacity (Output) | 2 A per channel (resistive load) |

| Communication Interface | Profibus DP, Ethernet (via controller) |

| Safety Integrity Level | SIL 3 (IEC 61508/61511 compliant) |

| Operating Temperature | -40°C to +70°C |

| Redundancy Support | Hot-swappable in redundant configurations |

| Electromagnetic Compatibility (EMC) | Compliant with EN 61000-6-2/3 |

HIMA Z7128

3. Advantages and Features

The HIMA Z7128 stands out for its dual-channel redundancy and built-in self-diagnostics, which continuously monitor signal integrity and module health, reducing mean time to repair (MTTR) by up to 30%. Its SIL 3 certification ensures compliance with the highest safety standards, making it suitable for applications where failure could lead to severe consequences.

The module’s universal signal compatibility allows it to interface with various field devices without additional hardware, simplifying system design and inventory management. Its rugged construction and wide operating temperature range make it ideal for harsh industrial environments, while its low power consumption (less than 5W per module) contributes to energy efficiency and cost savings.

4. Application Areas and Use Cases

The HIMA Z7128 is widely deployed in industries such as:

- Chemical and petrochemical processing

- Oil and gas production

- Power generation and distribution

- Pharmaceutical and biotech manufacturing

Case Study: A European power plant integrated the HIMA Z7128 into its turbine safety system to monitor critical parameters like vibration, temperature, and pressure. The module’s real-time diagnostics and SIL 3 compliance enabled the plant to achieve a 99.99% availability rate, minimizing unplanned outages and ensuring safe operation during extreme weather conditions.

5. Competitive Landscape Comparison

Compared to similar I/O modules, the HIMA Z7128 offers superior diagnostic coverage (over 99% fault detection rate) and flexibility, supporting a mix of input and output channels in a single module. Its advanced error correction and noise immunity features reduce the risk of spurious trips, a common challenge in industrial environments with high electromagnetic interference.

The module’s hot-swappable design allows maintenance without system shutdown, a key advantage over non-redundant alternatives, while its standardized communication protocols ensure seamless integration with both legacy and modern control systems.

HIMA Z7128

6. Selection Recommendations

When selecting the HIMA Z7128, consider the following:

- Signal Requirements: Verify that the module supports the input/output types (digital/analog) and channel counts needed for your application.

- Safety Compliance: Ensure its SIL 3 rating aligns with the safety integrity level specified by your system’s risk assessment.

- Environmental Conditions: Confirm that the operating temperature, humidity, and vibration tolerance match your site’s conditions, especially for outdoor or harsh installations.

- System Integration: Check compatibility with your existing controller’s communication protocol (e.g., Profibus, Ethernet) to avoid integration issues.

7. Usage and Installation Notes

- Safety System Design: Follow IEC 61511 guidelines for configuring I/O modules in safety instrumented systems to maintain overall system integrity.

- Electrical Installation: Install the module in a grounded, shielded enclosure to comply with EMC standards and protect against voltage surges.

- Hot-Swap Procedure: Use HIMA’s approved tools to safely replace modules while the system is running, ensuring no interruption to safety functions.

- Firmware Management: Regularly update firmware through the controller’s configuration software to access the latest diagnostic features and security patches.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.