Description

1. Product Description

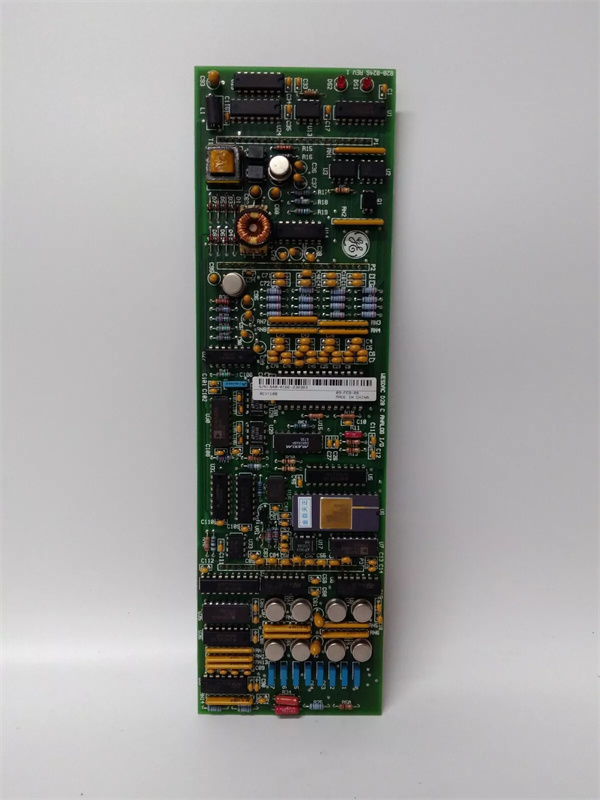

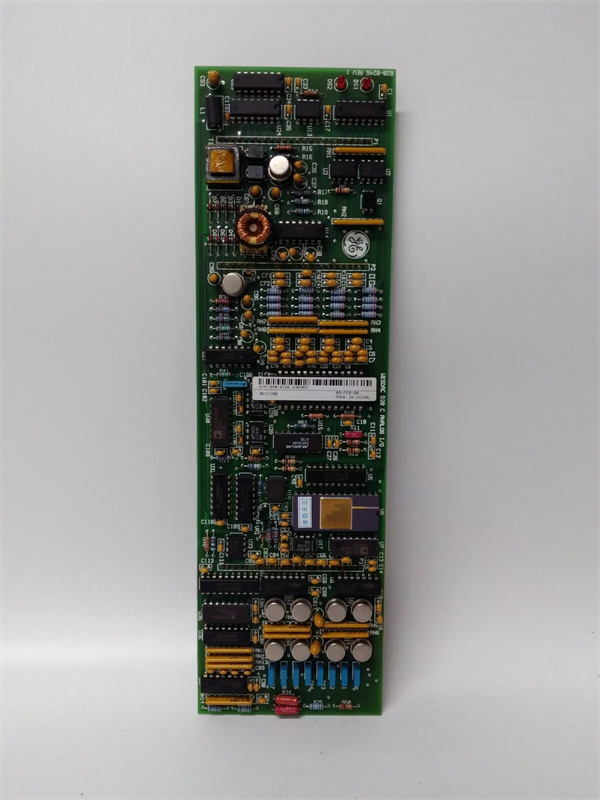

The D20C consists of two detachable components: the Western D20Ctermination board for field wiring and the WESDAC D20C module for signal processing and communication with the D20 processor. It supports up to 16 digital inputs (12–130 VDC), 8 relay outputs (3 A max), and optional analog channels (16 analog inputs or 8 analog inputs/outputs). Key features include surge protection, noise filtering, and dual D.20 Link ports for high-speed data exchange. The module’s 8-bit Freescale 68HC11 MPU (2 MHz clock speed) ensures real-time control with minimal latency, while 24 KB EPROM and 32 KB SRAM provide ample memory for complex logic.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Function | Analog/digital I/O processing for industrial control |

| Compatibility | GE D20/D200 substation control systems |

| Digital I/O | 16 inputs (12–130 VDC), 8 relay outputs (3 A max) |

| Analog I/O (Optional) | 16 bipolar inputs (±35 VDC, 14-bit resolution) or 8 inputs/outputs (0–20 mA, 12-bit) |

| Communication | RS-232 (9600 baud) for maintenance, D.20 Link for system integration |

| Power Requirements | 20–60 VDC, 5 W typical / 11 W full load |

| Dimensions | 19″ x 5.25″ x 2.5″ (assembly) |

| Operating Temperature | -40°C to +70°C |

| Redundancy | Supports dual-channel configuration (TMR-ready) |

WESDAC D20C

3. Advantages and Features

-

Modular Design:

- The detachable Western D20C termination board simplifies field wiring, while the WESDAC D20C handles signal processing and communication.

- Optional analog daughter boards allow customization for specific applications (e.g., temperature monitoring or valve control).

-

Reliability:

- Built-in surge protection (MOVs) and noise filters reduce unplanned outages by up to 35% in high-interference environments.

- Industrial-grade components (e.g., red-coated diodes) ensure stability in extreme temperatures and vibrations.

-

Flexible Configuration:

- Jumper switches and DIP switches enable custom signal mapping and address assignment.

- Supports dual D.20 Link ports for daisy-chaining multiple modules or redundant system setups.

-

Efficient Processing:

- 8-bit Freescale 68HC11 MPU with 2 MHz clock speed ensures real-time control with minimal latency.

- 32 KB SRAM and 24 KB EPROM provide ample memory for complex logic and data storage.

4. Application Areas and Use Cases

Industries:

- Power Generation: Substation automation, turbine control, and grid monitoring.

- Oil & Gas: Pipeline SCADA systems, compressor stations, and refinery processes.

- Manufacturing: Motor control centers, conveyor systems, and quality assurance.

Use Case:

A 300 MW gas-fired power plant in the Middle East uses the D20C to interface 16 temperature sensors and 8 valve actuators with the D20 control system. The module’s surge protection reduced downtime by 35% over five years, while its modular design simplified expansion during plant upgrades.

A 300 MW gas-fired power plant in the Middle East uses the D20C to interface 16 temperature sensors and 8 valve actuators with the D20 control system. The module’s surge protection reduced downtime by 35% over five years, while its modular design simplified expansion during plant upgrades.

5. Competitive Comparison

| Feature | D20C | Alternative Solutions |

|---|---|---|

| Analog Precision | 14-bit resolution (analog inputs) | 12-bit typical |

| Redundancy | Built-in dual-channel support | Requires external modules |

| Signal Conditioning | Integrated surge protection | Optional add-ons |

| Legacy Compatibility | Direct replacement for D20/D200 systems | Requires adapters |

| Cost Efficiency | Refurbished units available at 40% cost | New units only |

WESDAC D20C

6. Selection Recommendations

-

System Compatibility:

- Verify integration with D20/D200 processors (e.g., D20M++, D20ME) and power supply modules (DS200PWR01AAA).

- Avoid mixing revisions (e.g., Rev A vs. Rev D) due to potential backward incompatibility.

-

Environment:

- For offshore or high-vibration settings, pair with GE’s IP66-rated enclosures and shock mounts.

- Ensure proper grounding to prevent ESD damage.

-

Maintenance Strategy:

- Source refurbished units from certified suppliers with 1–3 year warranties.

- Schedule annual inspections of connectors and solder joints.

-

Future-Proofing:

- Consider migrating to GE’s Mark VIe or PACSystems RX3i for advanced features (e.g., Ethernet/IP, IoT integration).

7. Precautions and Best Practices

-

Installation:

- Use anti-static wrist straps during handling and secure the module in a grounded chassis with 10 cm clearance for airflow.

- Follow GE’s wiring guidelines to avoid short circuits.

-

Configuration:

- Use GE’s D20 Config Pro software for signal mapping and diagnostics.

- Validate D.20 Link termination resistors (120 Ω) to prevent signal reflections.

-

Troubleshooting:

- Check LED indicators: Green = normal operation; Amber = signal fault.

- Replace failed components (e.g., MOVs, relays) with GE-certified parts.