Description

Product Overview

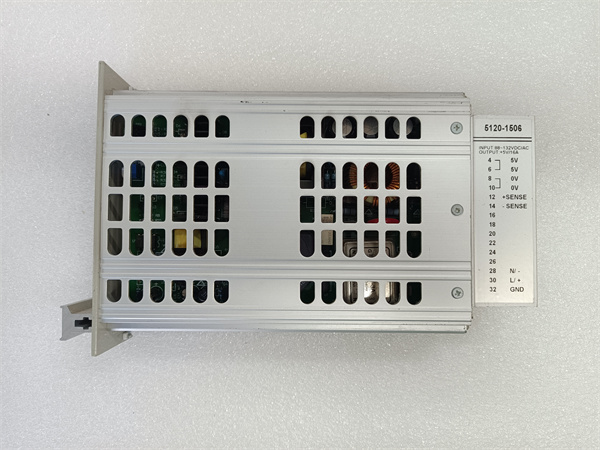

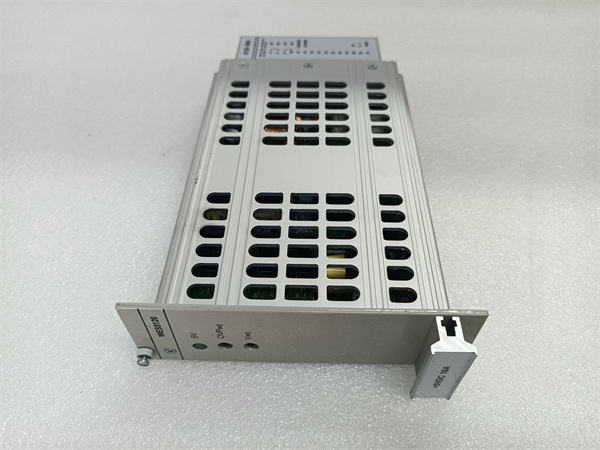

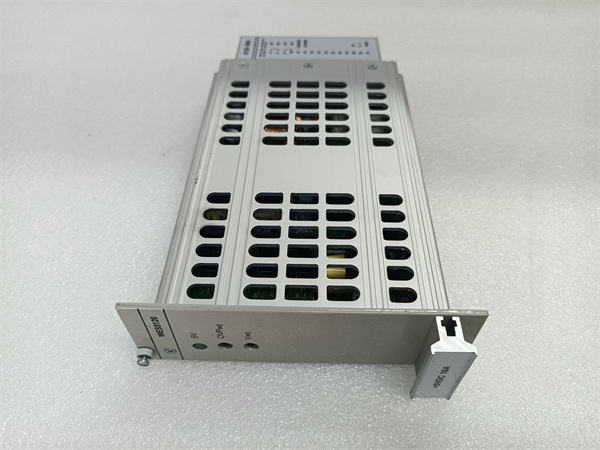

The GE WES5120 5120 – 1506 is a high – performance control module engineered for industrial automation applications. As part of GE’s advanced industrial control solutions, this module plays a pivotal role in enhancing the efficiency and reliability of diverse industrial processes.

This WES5120 5120 – 1506 module serves as a central control unit, coordinating the operation of remote I/O devices to ensure seamless system performance. It is equipped with a high – performance processor that can handle complex control tasks with ease. This enables it to manage intricate industrial operations, such as those in manufacturing lines or process control systems. With extensive communication capabilities, including ports for Ethernet, RS – 232, and RS – 485, it can establish connections with a wide range of devices, facilitating data exchange and system integration. Its robust construction allows it to withstand the harsh conditions often found in industrial environments, including shock, vibration, and extreme temperatures.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | WES5120 5120 – 1506 |

| Manufacturer | GE |

| Product Type | Control Module |

| Input Voltage | 120 VAC / 24V DC |

| Output Voltage | 24 VDC |

| Communication Interface | RS 485, Ethernet, RS – 232 |

| Operating Temperature Range | – 40 °C to + 85 °C |

| Storage Temperature Range | – 55 °C to + 85 °C |

| Dimensions | 12.7 cm x 10.2 cm x 6.4 cm |

| Weight | 0.3 kg |

| Certifications | CE, UL, CSA |

| Power Supply | 24 VDC |

| Max I/O Handling | Flexible support for various sensors and actuators |

| Communication Protocols | Supports Modbus, Ethernet, and other industrial protocols |

WES5120 5120-1506

Main Features and Advantages

High – Performance Processing

The WES5120 5120 – 1506‘s high – performance processor enables it to execute complex control algorithms rapidly. This ensures precise control over industrial processes, reducing errors and increasing productivity. Whether it’s managing the speed of conveyor belts in a factory or controlling the flow of chemicals in a process plant, the module can handle the tasks with high accuracy.

Versatile Communication

With multiple communication interfaces and support for various industrial protocols like Modbus and Ethernet, the module can integrate smoothly with different devices and systems. This versatility allows for easy expansion of the industrial network and seamless data transfer between components. It can communicate with sensors to collect real – time data and send control signals to actuators, enabling efficient operation of the overall system.

Rugged Design

Built to endure harsh industrial conditions, the module’s rugged construction makes it highly reliable. It can resist shock and vibration, which are common in industrial settings. The wide operating temperature range ensures that it can function properly in both extremely cold and hot environments, such as in refrigerated warehouses or near furnaces in steel mills. This reliability reduces downtime and maintenance costs, as the module can operate continuously without frequent failures.

Flexible Programming

The WES5120 5120 – 1506 supports programming languages like ladder logic, function block diagram, and structured text. This flexibility allows engineers to choose the most suitable programming method based on the application requirements. It makes the development of control strategies more convenient and efficient, as different teams may be more familiar with different programming languages.

WES5120 5120-1506

Application Field

Factory Automation

In factory automation, the GE WES5120 5120 – 1506 is used to control a variety of equipment. It can manage the operation of robots, ensuring they perform tasks such as welding, painting, and assembly with precision. The module also controls conveyors, regulating the movement of products along the production line. Additionally, it can interface with machine tools, adjusting their settings to optimize machining processes. By coordinating these different components, it enhances the overall efficiency and productivity of the factory.

Process Control

For process control applications, such as in chemical manufacturing or food processing, the WES5120 5120 – 1506 is crucial. It can monitor and control variables like temperature, pressure, and flow rate in chemical reactors or food processing equipment. The module collects data from sensors placed throughout the process and uses this information to adjust actuators, such as valves and pumps, to maintain optimal process conditions. This helps in ensuring product quality, reducing waste, and improving the overall efficiency of the process.

Machine Control

The module is suitable for controlling machines ranging from small CNC units to large industrial presses. In a CNC machine, it can control the movement of the cutting tool, ensuring accurate machining of parts. For large industrial presses, it can manage the pressure and timing of the pressing operation. The WES5120 5120 – 1506‘s ability to handle complex control tasks makes it an ideal choice for machine control applications, where precision and reliability are essential.

Related Products

- GE WES5302: Another field controller master unit from GE, similar to the WES5120 5120 – 1506 but may have different I/O capabilities or communication protocol emphases, suitable for applications with specific requirements.

- GE Fanuc I/O Modules: These modules can be connected to the WES5120 5120 – 1506 to expand its input and output capabilities, allowing it to interface with more sensors and actuators in an industrial system.

- GE Ethernet – based Sensors and Actuators: Can communicate with the WES5120 5120 – 1506 through its Ethernet interface. Sensors provide real – time data, and actuators receive control signals from the module for coordinated operation.

- GE Power Supply Modules: Required to provide a stable 24 VDC power supply for the WES5120 5120 – 1506. Different power supply modules may offer additional features like over – voltage protection.

- GE Proficy Machine Edition Software: This software can be used to program the WES5120 5120 – 1506, providing tools for creating control strategies using the supported programming languages.

Installation and Maintenance

Pre – installation preparation: Before installing the GE WES5120 5120 – 1506, verify that the power supply voltage is either 120 VAC or 24V DC as required. Check the installation area for any potential sources of interference, and ensure it is clean and dry. Read the installation manual thoroughly to understand the proper mounting and wiring procedures. Prepare the necessary tools, such as screwdrivers and wire strippers. Mount the module securely in the control cabinet, making sure it is properly grounded. Connect the communication cables and power cables following the wiring diagrams provided, ensuring all connections are tight.

Maintenance recommendations: Regularly inspect the WES5120 5120 – 1506 for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the temperature of the module during operation to ensure it remains within the specified range. Clean the module periodically to prevent dust accumulation, which could affect its performance. Check the communication status to ensure data is being transferred correctly. If any issues arise, refer to the troubleshooting guide in the user manual. In case of complex problems, contact GE’s technical support team for assistance. Replace any worn – out components promptly to maintain the module’s reliability.

Product Guarantee

GE offers a comprehensive product guarantee for the WES5120 5120 – 1506. The module is rigorously tested during manufacturing to meet high – quality standards. GE provides a standard warranty period, during which any defects in materials or workmanship will be rectified free of charge. Their technical support team is available to assist customers with installation, configuration, and any technical issues that may occur during the product’s lifespan. Whether it’s a problem with communication, I/O functionality, or programming, GE is committed to providing timely solutions, ensuring the WES5120 5120 – 1506 operates smoothly and reliably, and giving customers confidence in their investment.