Description

Product Overview

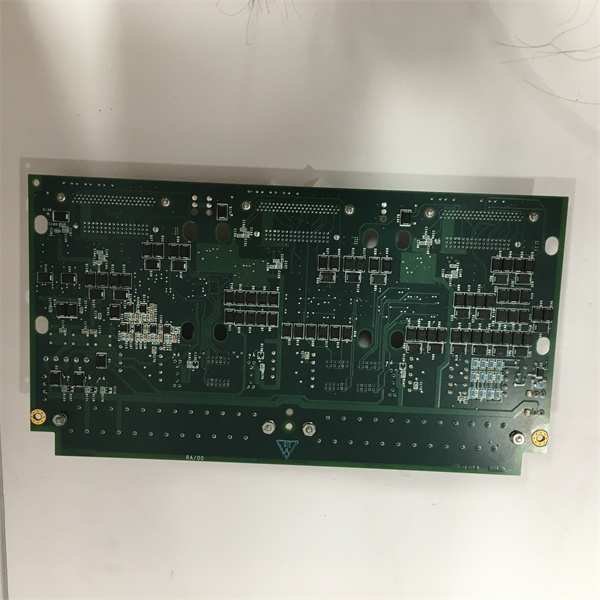

The GE UR8GH is a high – performance industrial control module designed to meet the complex demands of modern automation systems. As part of GE’s advanced product lineup, it offers reliable and precise control, making it a go – to choice for various industrial applications. This module is engineered to provide seamless integration into existing setups, ensuring enhanced efficiency and productivity.

The UR8GH comes with a built – in Ethernet user – enabled communication feature. It supports SRTP and Modbus TCP/IP application protocols, providing a real – time link for connected systems. This allows for quick data transfer and efficient communication between different components in an industrial network. With its powerful processing capabilities, it can handle up to 512 I/O points, making it suitable for complex industrial processes that require a large number of input and output connections. The module also features an integrated motion control function, enabling high – performance operation in point – to – point applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | UR8GH |

| Manufacturer | GE |

| Product Type | Control Module |

| Operating Voltage | 220 V |

| Output Frequency | 50 or 51 |

| Communication Protocols | SRTP, Modbus TCP/IP |

| Max I/O Points | 512 |

| Protection Class | IP65 |

| Heat Dissipation | 12W |

| Bus Circuit Requirement | 480 mA |

| Dimensions | Approx. 263×58×28 mm |

| Weight | 4.3 kg |

| Country of Origin | United States of America |

Main Features and Advantages

Robust Communication Capabilities

The UR8GH‘s support for SRTP and Modbus TCP/IP protocols ensures secure and efficient data transfer. In industrial settings where real – time monitoring and control are crucial, this enables seamless communication between the module and other devices, such as sensors, actuators, and control systems. The Ethernet – based communication also allows for easy integration into larger industrial networks, facilitating remote monitoring and control.

High – Capacity I/O Handling

With the ability to manage up to 512 I/O points, the UR8GH can handle the complex input and output requirements of large – scale industrial processes. This high – capacity I/O handling is beneficial for applications that involve multiple sensors, switches, and actuators, ensuring accurate control and data acquisition.

Integrated Motion Control

The integrated motion control feature of the UR8GH is a significant advantage. It enables high – performance control in point – to – point applications, which is essential for machinery that requires precise movement, such as robotic arms in manufacturing plants or automated guided vehicles in warehouses. This feature helps in achieving smooth and accurate motion, leading to improved product quality and production efficiency.

Flexible Programming Options

It is programmable with Proficy Logic Developer PLC – Machine Edition and supports a wide range of programming languages, including Ladder Diagram (LDI), Instruction List (IL), Structural Text (ST), and C Block. This flexibility allows engineers and programmers to choose the most suitable language for their specific application, making it easier to develop and implement control strategies.

IS200TSVCH1AED

Application Field

Manufacturing Industry

In manufacturing plants, the GE UR8GH is extensively used for machine control. For example, it can be employed to control the movement of automated assembly lines. By precisely managing the I/O points and using its motion control capabilities, it ensures that components are accurately assembled, reducing errors and increasing production speed. It also finds application in controlling robotic systems for tasks like pick – and – place operations, where the module’s high – speed and accurate control are crucial.

Energy Sector

In power generation facilities, the UR8GH is used for monitoring and controlling various processes. It can handle the complex I/O signals from sensors and actuators in power plants, such as those in steam turbines or generator systems. The module’s reliable communication capabilities enable real – time data transfer to the central control system, allowing operators to monitor and adjust the power generation process for optimal efficiency and stability.

Infrastructure Management

For infrastructure systems like water treatment plants, the UR8GH plays a vital role. It can control the pumps, valves, and other equipment in the treatment process. By accurately managing the I/O points and using its communication features to integrate with other components in the plant’s control network, it ensures the smooth operation of the water treatment process, maintaining the quality of treated water.

Related Products

- UR8AH: Similar to the UR8GH, but may have different I/O capabilities or communication protocol preferences. It can be used in applications where a slightly different configuration is required.

- UR6GH: A more compact option with a lower number of I/O points, suitable for smaller – scale industrial applications where space is limited and the complexity of the control system is not as high.

- GE Proficy Logic Developer PLC – Machine Edition: The software used to program the UR8GH. It provides the necessary tools and programming languages for customizing the module’s functionality according to specific application needs.

- GE Ethernet – based sensors and actuators: These devices can be connected to the UR8GH via its Ethernet communication interface. They work in tandem with the module, with the sensors providing input data and the actuators receiving control signals from the UR8GH for seamless operation in an industrial system.

- GE power supply modules: These are required to provide the 220 V operating voltage for the UR8GH. Different power supply modules may vary in terms of power capacity and additional features, but they all ensure stable power supply to the module.

Installation and Maintenance

Pre – installation preparation: Before installing the GE UR8GH, ensure that the installation area meets the environmental requirements, such as an appropriate temperature range and protection from excessive dust and moisture, as per the IP65 rating. Check the power supply to confirm it can provide a stable 220 V. Verify the compatibility of the module with other components in the system, including communication devices and I/O equipment. Read the installation manual thoroughly to understand the proper mounting and wiring procedures. Use appropriate tools to carefully mount the module in the designated location, ensuring a secure fit. Connect the communication cables and power cables following the wiring diagrams provided.

Maintenance recommendations: Regularly inspect the UR8GH for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the communication status to ensure data is being transferred correctly. Check the temperature of the module during operation to ensure it remains within the normal range, as excessive heat can affect performance. Clean the module periodically to maintain its IP65 protection level and prevent dust from accumulating, which could cause overheating or electrical issues. If any issues arise, refer to the detailed troubleshooting guide in the user manual. In case of complex problems, contact GE’s technical support team for assistance.

Product Guarantee

GE offers a comprehensive product guarantee for the UR8GH. The module is rigorously tested during the manufacturing process to ensure it meets high – quality standards. GE provides a standard warranty period, during which any defects in materials or workmanship will be rectified free of charge. Their experienced technical support team is available to assist customers with installation, configuration, and any technical issues that may occur during the product’s lifespan. Whether it’s a problem with communication, I/O functionality, or programming, GE is committed to providing timely solutions, ensuring the UR8GH operates smoothly and reliably, and giving customers confidence in their investment.