Description

Product Overview

The GE KBGA2 is a high – performance control module designed for industrial automation systems. It belongs to the Marks VI series, occupying a crucial position in GE’s industrial control product lineup. This module is engineered to offer reliable and stable control functions, serving as a key component in various industrial automation scenarios.

With advanced technology, the GE KBGA2 provides powerful processing capabilities, enabling it to handle complex control tasks with ease. It has a user – friendly design that allows for seamless integration into different systems, offering users high flexibility. Whether it is used in new system construction or existing system upgrades, the GE KBGA2 can meet diverse application requirements, playing a significant role in enhancing production efficiency and system reliability.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | KBGA2 |

| Manufacturer | GE |

| Product Type | Control Module |

| Power Requirements | 110 – 240 V AC |

| Operating Temperature Range | – 40 °C to 85 °C |

| Storage Temperature Range | – 55 °C to 105 °C |

| Humidity Range | 5 % to 95 %, non – condensing |

| Dimensions | 15 x 20 x 5 cm |

| Weight | 1.2 kg |

| Communication Interfaces | Ethernet, RS 232/RS 485 |

| Memory | 32 KB user memory1 |

| I/O Capacity | 4K I/O1 |

| Logic Execution Speed | 0.22 msec/K1 |

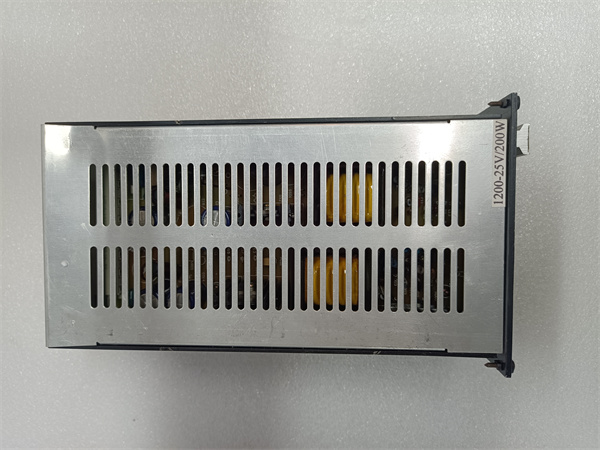

GE WES5123-1200

Main Features and Advantages

The GE KBGA2 features a compact and robust design. Its small size allows for efficient use of space in control cabinets, while being made of high – quality materials, it can withstand harsh industrial environments, ensuring long – term reliable operation.

This module supports multiple communication interfaces such as Ethernet and RS 232/RS 485, enabling seamless connection with other devices and systems, which is essential for modern industrial automation systems that require extensive data exchange and control. It also has expandable processing power, allowing users to build a system that meets current needs and can be easily upgraded in the future without changing the software1. In addition, the GE KBGA2 supports a variety of programming languages, including ladder diagram (LDI), instruction list (IL), structured text (ST), and C block, providing users with flexible programming options1.

Application Field

The GE KBGA2 has a wide range of applications in various industrial fields. In the power generation industry, it can be used for the control and monitoring of power generation equipment to ensure the stable operation of the power generation process. In the manufacturing industry, it is suitable for controlling production lines, such as in complex motion control, high – speed packaging, and injection molding applications, helping to improve production efficiency and product quality. In the process industry, it can be applied to process control in water treatment, food processing, and other fields, precisely controlling process parameters to meet process requirements. Moreover, it also has excellent performance in applications such as elevator control and material handling, being able to provide reliable control solutions for these specific scenarios.

Related Products

- GE KBGA1: It is a product in the same series as KBGA2, with similar functions but perhaps different in some specific parameters or performance.

- GE 350: It is also a controller – related product that can work with the GE KBGA2 in some systems, providing additional control or I/O functions.

- GE Proficy Logic Developer: It is a programming software that is used to program the GE KBGA2 and other related control modules, facilitating users to develop control programs.

- GE Ethernet Bus Module: It can be used in conjunction with the GE KBGA2 to realize Ethernet – based communication and data exchange functions.

- GE Remote I/O Module: It is used to expand the I/O capabilities of the GE KBGA2 system, enabling remote monitoring and control of I/O signals.

GE WES5123-1200

Installation and Maintenance

Pre – installation preparation: Before installing the GE KBGA2 module, make sure the installation environment meets the requirements, including appropriate temperature, humidity, and power supply conditions. Check the integrity of the module and related accessories, and prepare the necessary installation tools. Read the installation manual carefully to understand the installation steps and precautions.

Maintenance recommendations: Regularly check the operating status of the GE KBGA2 module, including monitoring the temperature, humidity, and power supply of the working environment. Clean the module regularly to prevent dust and dirt from affecting its performance. Check the connection status of the communication interface and I/O port to ensure reliable connection. If any problems are found, contact the professional technical support team in time for repair and maintenance.

Product Guarantee

GE provides a comprehensive product guarantee for the KBGA2 module. It ensures the quality of the product, promising that the module will be free from defects in materials and workmanship within a certain period. In case of any quality problems, GE will provide timely after – sales service, including repair, replacement, and technical support. The professional technical team is always available to help customers solve various problems encountered during the use of the product, demonstrating GE’s confidence in product quality and its commitment to customer satisfaction.