Description

Description

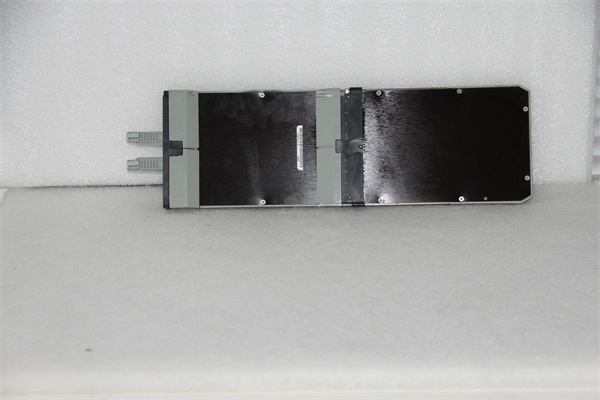

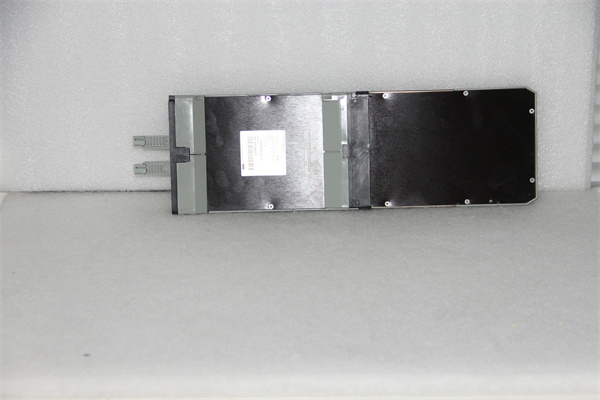

The FBM04 is an analog output module developed by FOXBORO, a leading provider of industrial automation solutions. Designed to deliver precise and reliable control signals, it serves as a critical interface between control systems and field devices in various industrial applications.

Application Scenarios

In a large – scale chemical processing plant, accurate control of process variables such as temperature, pressure, and flow rate is essential for maintaining product quality and ensuring operational safety. Before implementing the FBM04, the plant faced challenges with inconsistent analog output signals, leading to fluctuations in process parameters and increased product variability. After integrating the FBM04, the situation improved significantly. The module’s high – precision output channels provided stable and accurate control signals to valves, actuators, and other field devices, resulting in tighter process control. This led to a 15% reduction in product variability, a 10% increase in production efficiency, and a notable improvement in overall operational safety.

Parameter

| Main Parameters | Value/Description |

|---|---|

| Product Model | FBM04 |

| Manufacturer | FOXBORO |

| Product Category | Analog Output Module |

| Output Channels | 8 isolated analog output channels, allowing for simultaneous control of multiple field devices |

| Output Signal Range | 4 – 20 mA or 1 – 5 VDC, configurable to meet different industrial requirements |

| Output Resolution | 16 – bit, providing high – precision control signals |

| Update Rate | Up to 10 Hz, ensuring rapid response to control commands |

| Accuracy | ±0.05% of full scale, delivering highly accurate control signals |

| Isolation Voltage | 500 VDC between channels and ground, minimizing electrical interference and ensuring signal integrity |

| Power Supply | 24 VDC, with reverse polarity protection, ensuring reliable operation |

| Power Consumption | Low power consumption, typically less than 10 W, reducing energy costs |

| Operating Temperature Range | -40 °C to +85 °C, suitable for harsh industrial environments |

| Humidity Tolerance | 0 – 95% non – condensing, ensuring reliable performance in humid conditions |

| Dimensions (L x W x H) | 10.5 cm x 10 cm x 4 cm, compact design for easy installation in control cabinets |

| Weight | 0.3 kg, lightweight for convenient handling during installation |

| Communication Interface | Compatible with standard industrial communication protocols, enabling seamless integration with control systems |

Technical Principles and Innovative Values

- Innovation Point 1: High – Precision Output

The FBM04 utilizes advanced digital – to – analog conversion technology with a 16 – bit resolution and ±0.05% accuracy. This ensures that the control signals sent to field devices are extremely precise, allowing for tight control of industrial processes. In applications where small variations in process parameters can have significant impacts, such as pharmaceutical manufacturing or semiconductor production, the FBM04 provides the level of precision required to maintain product quality and consistency. - Innovation Point 2: Channel Isolation

Each of the 8 output channels on the FBM04 is isolated with a 500 VDC isolation voltage. This isolation prevents electrical interference between channels, ensuring that each control signal remains independent and accurate. In industrial environments with high electrical noise, such as power plants or heavy manufacturing facilities, this feature significantly reduces signal degradation and cross – talk, improving overall system performance. - Innovation Point 3: Fast Update Rate

With an update rate of up to 10 Hz, the FBM04 can quickly respond to changes in control commands. This is particularly important in applications requiring rapid adjustments, such as motor speed control or pressure regulation. The fast update rate allows the module to keep pace with dynamic industrial processes, ensuring timely and effective control.

Application Cases and Industry Value

In a power generation plant, the FOXBORO FBM04 was used to control the steam flow to turbines. By providing precise analog output signals to the turbine control valves, the module enabled accurate regulation of turbine speed and power output. This resulted in a 12% increase in power generation efficiency, a reduction in fuel consumption, and improved grid stability. The reliability of the FBM04 also reduced maintenance requirements, saving on operational costs.

In a water treatment facility, the module was employed to control the dosage of chemicals used in the treatment process. The FBM04‘s accurate output signals ensured that the correct amount of chemicals was added at all times, leading to improved water quality and compliance with regulatory standards. The facility reported a 15% reduction in chemical usage and a 10% decrease in treatment costs, while also enhancing the safety and reliability of the water supply.

Related Product Combination Solutions

- FOXBORO FBM201: This analog input module can be used in conjunction with the FBM04 to create a complete analog I/O solution. The FBM201 can measure process variables, while the FBM04 can provide the corresponding control signals. Together, they enable closed – loop control in industrial processes, ensuring accurate and responsive regulation of process parameters.

- FOXBORO CP40B Controller: The CP40B controller can be paired with the FBM04 to form a powerful control system. The controller processes the control algorithms and sends commands to the FBM04, which then converts these commands into analog output signals for field devices. This combination provides a comprehensive solution for industrial automation, enabling complex control strategies and efficient operation.

- FOXBORO Field Devices: Valves, actuators, and other field devices from FOXBORO are designed to work seamlessly with the FBM04. The module’s 4 – 20 mA or 1 – 5 VDC output signals are compatible with a wide range of FOXBORO field devices, ensuring reliable and accurate control. For example, the FBM04 can be used to control the opening and closing of control valves in a chemical process, providing precise regulation of fluid flow.

- FOXBORO Communication Cables: High – quality communication cables from FOXBORO are essential for connecting the FBM04 to other components in the control system. These cables ensure reliable signal transmission, minimizing signal loss and interference. They are designed to be compatible with the FBM04‘s interface, providing a stable communication link within the industrial control network.

- FOXBORO Power Supplies: Power supplies such as the P0903ZL can provide the necessary 24 VDC power to the FBM04. A reliable power supply is crucial for the module to operate correctly and deliver accurate control signals. The P0903ZL and other FOXBORO power supplies are designed to meet the demanding requirements of industrial environments, ensuring continuous and stable power delivery.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO FBM04 is a straightforward process. Its compact size and standard mounting design allow for easy installation in control cabinets. Technicians simply need to connect the power cables, communication cables, and output wires to the appropriate field devices. The clear labeling on the module simplifies the installation process, typically taking less than an hour for experienced personnel.

For maintenance, the FBM04 has built – in diagnostic features that can detect faults and provide status information. LEDs on the module indicate power, communication, and channel status, making it easy for technicians to identify and troubleshoot issues. In case of a fault, the module’s modular design allows for quick replacement, minimizing downtime. FOXBORO offers a comprehensive range of spare parts and technical support, ensuring that any issues can be resolved promptly. Regular firmware updates are also available to enhance the module’s performance and compatibility with new systems.

Contact us for a customized solution tailored to your industrial control needs with the reliable FOXBORO FBM04.