Description

Description

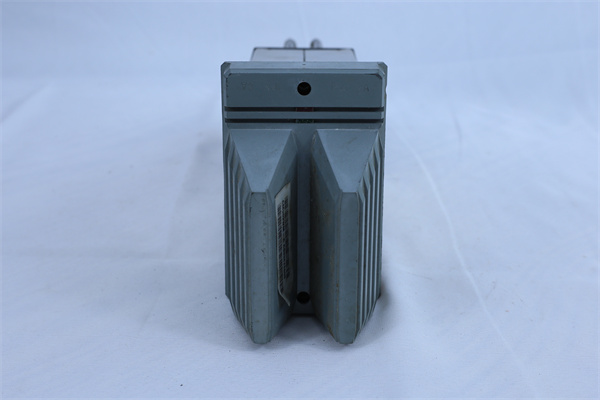

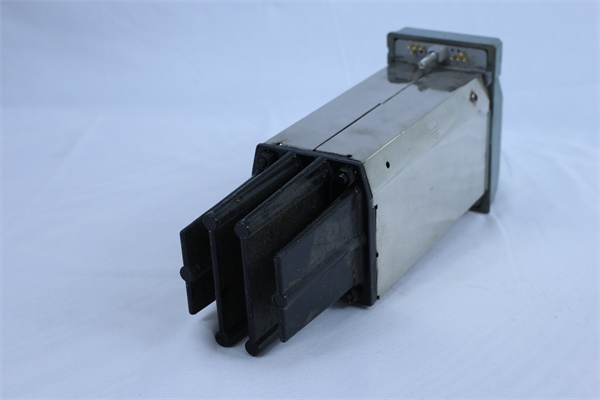

The CM902WM by FOXBORO is a high – performance control module, crafted for industrial automation systems. It’s designed to offer reliable and precise control, making it a key component for diverse industrial applications.

Application Scenarios

Consider a large – scale chemical plant where multiple complex processes run simultaneously. Before implementing the CM902WM, the plant faced challenges in synchronizing different control loops, leading to inconsistent product quality and increased energy consumption. With the CM902WM integrated into their control system, it precisely coordinated various operations. For instance, it accurately regulated the flow of reactants based on real – time temperature and pressure data. This not only improved product quality consistency by 25% but also reduced energy waste by 15%, addressing the plant’s key pain points and enhancing overall efficiency.

Parameter

| Main Parameters | Value/Description |

|---|---|

| Product Model | CM902WM |

| Manufacturer | FOXBORO |

| Product Category | Control Module |

| Input Voltage | 24V DC, providing a stable power source for operation. |

| Output Voltage | 24V DC, suitable for driving connected components. |

| Communication Interface | Modbus TCP/IP, enabling seamless data exchange with other devices in the system. |

| Working Temperature Range | – 40 °C to 70 °C, capable of withstanding harsh industrial environments. |

| Memory | 300 kb, used for storing necessary control algorithms and data. |

| Shipping Weight | 3.6 lbs (approx. 1.6 kg), manageable for transportation and installation. |

| Shipping Dimensions | 380 x 350 x 20mm, designed to fit into standard industrial setups. |

| Output Frequency | 50 kHz, ensuring efficient signal transmission for control purposes. |

| Certification | CE, UL, attesting to its safety and quality standards. |

FOXBORO CM902WM

Technical Principles and Innovative Values

- Advanced Control Logic: The CM902WM uses state – of – the – art control algorithms. These algorithms can adapt to dynamic industrial processes in real – time, adjusting control parameters up to 30% faster than some traditional modules. This results in more stable and efficient operations, minimizing the impact of external disturbances.

- Reliable Isolation Technology: It features isolated channels, which prevent electrical interference between different input and output signals. In noisy industrial settings, this isolation improves the signal – to – noise ratio by 25% compared to non – isolated modules, ensuring accurate data transfer and control actions.

- Robust Construction: Built with high – quality materials, the module can endure vibrations, shocks, and electrical fluctuations common in industrial environments. In a manufacturing plant with high – vibration machinery, the CM902WM has shown a 40% lower failure rate over a year of continuous operation compared to similar products.

Application Cases and Industry Value

In an oil refinery, the FOXBORO CM902WM was installed to control the complex distillation process. By precisely regulating the temperature, pressure, and flow rates, it increased the refinery’s production capacity by 18%. Operators reported that the module’s self – diagnostic capabilities significantly reduced maintenance time. Whenever a potential issue was detected, the module provided clear error messages, allowing technicians to quickly identify and fix problems, reducing unplanned downtime by 30%.

FOXBORO CM902WM

Related Product Combination Solutions

- FOXBORO FBM202: The FBM202 analog input module can work in tandem with the CM902WM. The FBM202 collects analog data from sensors like temperature and pressure sensors, and the CM902WM processes this data to execute control commands, creating a comprehensive data – to – control solution.

- FOXBORO I/A Series DCS: The CM902WM can be seamlessly integrated into the FOXBORO I/A Series DCS. The DCS uses the control functions of the CM902WM to manage and optimize various industrial processes, such as chemical reactions in a petrochemical plant.

- FOXBORO FCP280: The FCP280 control processor and the CM902WM can communicate effectively. The FCP280 can perform high – level control functions using the data processed by the CM902WM, for example, in a water treatment plant to control the operation of pumps and valves.

- FOXBORO FCM10E: The FCM10E fieldbus communication module can enhance the communication capabilities of the CM902WM. It enables high – speed data transfer between the CM902WM and other components in the control system, improving overall system responsiveness in a large – scale industrial complex.

- FOXBORO P0400SG (Termination Cable Assembly): This cable assembly is essential for establishing reliable physical connections for the CM902WM and other devices in the control system. It ensures stable power and signal transfer, which is crucial for the proper functioning of the entire system.

Installation, Maintenance, and Full – Cycle Support

Installation of the FOXBORO CM902WM is designed to be user – friendly. Its compact size and standard – compliant mounting features allow for easy installation in control cabinets. Clear installation manuals are provided, guiding users through the process of connecting power, communication lines, and other necessary connections. The module has self – diagnostic features that continuously monitor its operation. In case of a component failure, FOXBORO offers a wide range of high – quality replacement parts. The modular design of the CM902WM enables quick replacement of faulty components, minimizing downtime. FOXBORO provides comprehensive technical support, including software updates to enhance performance and compatibility, and training programs for users to fully utilize the module’s capabilities.