Description

Product Overview

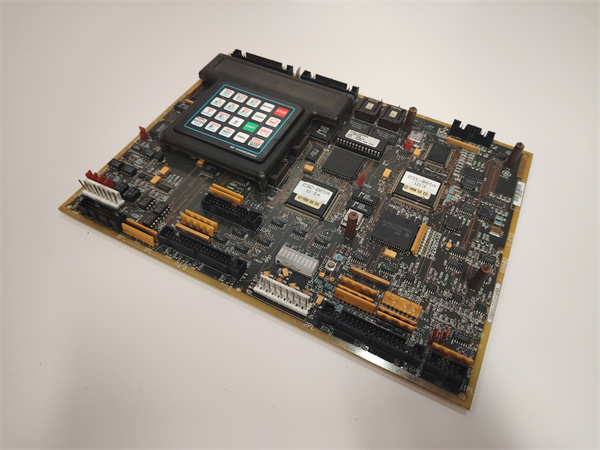

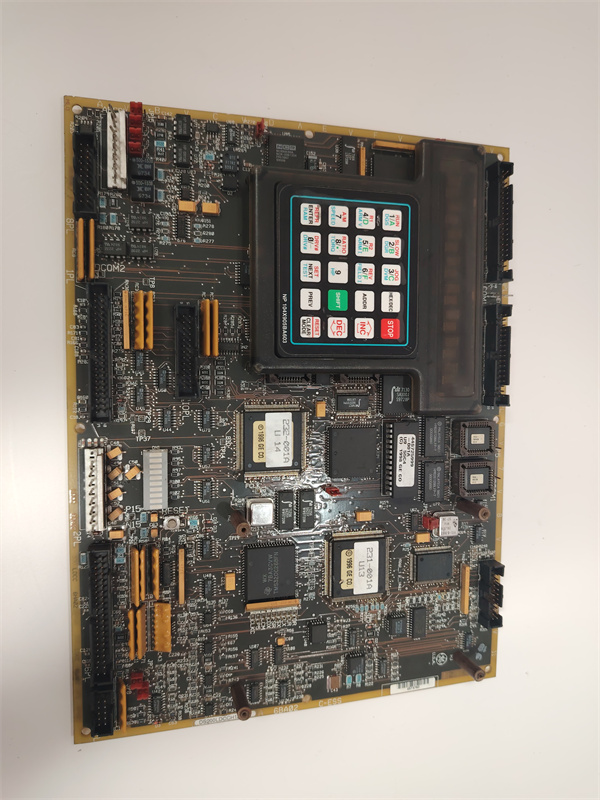

The GE DS200LDCCH1AKA is a high – performance digital I/O module by General Electric, a globally recognized leader in industrial automation. As an integral part of the GE Speedtronic Mark VI series, this module is designed to meet the complex demands of industrial control systems.

This module serves as a crucial interface between field devices and the control system. It plays a vital role in processing signals, ensuring seamless communication within the system. With its ability to handle multiple I/O tasks, the DS200LDCCH1AKA can precisely control and monitor various industrial processes. For instance, it can accurately manage the operation of servo valves, monitor the position of LVDT sensors, and process pulse rate inputs for flow monitoring. Its design emphasizes reliability, making it suitable for applications where continuous and stable operation is essential, such as in power generation plants, oil and gas refineries, and manufacturing facilities.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200LDCCH1AKA |

| Manufacturer | General Electric |

| Product Type | Digital I/O Module |

| Power Supply | Operates within a specified voltage range typical for industrial applications, e.g., 24V DC |

| Communication Protocols | Compliant with specific GE protocols for seamless system communication |

| Number of Servo Outputs | 2 |

| I/O for LVDT Sensors | Supports I/O for six LVDT position sensors |

| Active Pulse Rate Inputs | 2 for flow monitoring |

| Servo Coil Current Range | Can be selected between 10 – 120 mA via jumpers |

| Connector Type | Uses a 37 – pin cable for connection to VSVO processor board |

| Terminal Block Type | Euro – Block type with 42 or 36 terminals (depending on version) |

| Operating Temperature Range | Designed to operate in a wide temperature range suitable for industrial environments |

| Humidity Range | Can withstand a certain humidity level without condensation |

DS200LDCCH1AKA

Main Features and Advantages

Precise Signal Processing

The GE DS200LDCCH1AKA is engineered to process signals with high precision. In industrial applications, accurate signal processing is crucial for the proper functioning of equipment. For example, when controlling servo valves, it can precisely adjust the output based on the received signals, ensuring smooth and accurate movement of machinery. This precision minimizes errors and improves the overall quality of industrial processes.

Versatile I/O Configuration

With its diverse I/O capabilities, the module offers great versatility. The two servo outputs, I/O for six LVDT position sensors, and two active pulse rate inputs for flow monitoring enable it to interface with a wide range of field devices. In a manufacturing plant, it can simultaneously monitor the position of moving parts using LVDT sensors and control the flow of materials through pulse rate input processing, adapting to different industrial requirements with ease.

Reliable Design

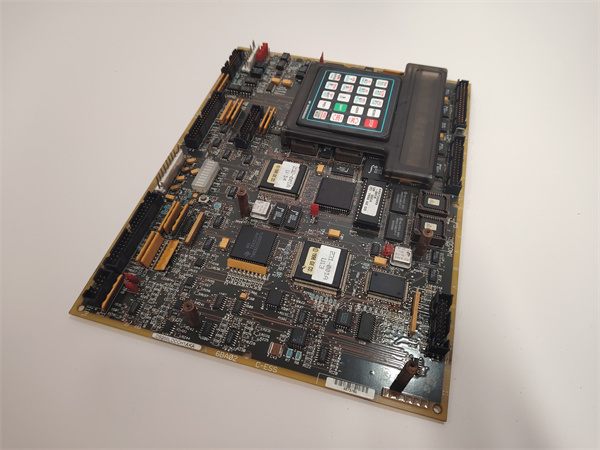

Built to endure harsh industrial conditions, the DS200LDCCH1AKA features a reliable design. Its components are selected for their durability, and it can operate within a wide temperature and humidity range. In power generation plants or oil and gas refineries, where the environment can be challenging, this module can maintain stable performance, reducing the risk of system failures and costly downtime.

Application Field

Power Generation

In power generation plants, the GE DS200LDCCH1AKA is used to control and monitor various aspects of the power generation process. It can manage the operation of turbines, ensuring that they run smoothly and efficiently. By processing signals from sensors that monitor parameters like temperature, pressure, and speed, it can make real – time adjustments to maintain optimal power generation. For example, it can control the opening and closing of servo valves to regulate the flow of steam or gas, thus controlling the turbine’s speed.

Oil and Gas

The oil and gas industry relies on the DS200LDCCH1AKA for critical control and monitoring tasks. In oil refineries, it can monitor the position of valves and pumps, ensuring proper flow of oil and gas through the pipelines. It can also process signals from sensors that detect leaks or pressure changes, triggering appropriate actions to prevent accidents. In offshore oil rigs, where the environment is harsh and reliable operation is essential, this module plays a key role in maintaining the safety and efficiency of the production process.

Manufacturing

Manufacturing facilities use the GE DS200LDCCH1AKA to enhance production efficiency and quality. In an automotive manufacturing plant, it can control the movement of robotic arms and conveyor belts. By accurately processing signals from sensors that detect the position of parts, it can ensure precise assembly. In a food and beverage manufacturing plant, it can monitor the filling and packaging processes, adjusting the flow of products to meet production standards.

DS200LDCCH1AKA

Related Products

- GE DS200LDCCH1AGA: Similar to the DS200LDCCH1AKA, it is also part of the GE Speedtronic Mark VI series. However, it may have differences in terms of specific I/O configurations or processing capabilities, making it suitable for slightly different industrial applications.

- GE Mark VI I/O Modules: These modules can be used in conjunction with the DS200LDCCH1AKA to expand the overall I/O capacity of the system. They are designed to interface with a variety of sensors and actuators, allowing for more comprehensive control in industrial processes.

- GE Speedtronic Mark VI Controllers: The DS200LDCCH1AKA is designed to work in harmony with these controllers. The controllers manage the overall control logic, and the DS200LDCCH1AKA serves as an important I/O interface, together ensuring the smooth operation of the industrial control system.

- GE DS200LDCCH1ANA: Another module in the same family. It likely shares some common features with the DS200LDCCH1AKA but may have specific variations in terms of functionality or compatibility, providing options for different industrial setups.

- GE IS200 Series Modules: These modules can complement the DS200LDCCH1AKA in larger industrial automation projects. They may offer additional features such as advanced communication capabilities or specialized control algorithms, enhancing the overall performance of the system.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200LDCCH1AKA, carefully check the module for any signs of damage during transit. Ensure that the installation environment meets the specified temperature and humidity requirements. Verify that the power supply voltage is within the recommended range. Thoroughly read the installation manual to understand the correct mounting procedure, which may involve securing the module in a designated slot in the control cabinet. Make sure all communication and power cables are of the appropriate type and are properly terminated.

Maintenance recommendations: Regularly monitor the DS200LDCCH1AKA for any signs of overheating, such as discolored components or an unusual smell. Clean the module periodically to prevent dust accumulation, as dust can affect its performance. Check the communication status with other devices in the control system to ensure data is being transmitted and received correctly. If any issues arise, consult the detailed troubleshooting guide provided by GE. Replace any worn – out components with genuine GE parts to maintain the module’s performance and reliability.

Product Guarantee

GE stands firmly behind the quality of the GE DS200LDCCH1AKA digital I/O module. The product comes with a comprehensive quality assurance program. In the event of a manufacturing defect within the specified warranty period, GE will either repair or replace the module free of charge. GE’s global network of technical support teams is available around the clock. Whether it’s providing guidance during installation, helping with configuration, or troubleshooting operational problems, these experts are committed to ensuring that the DS200LDCCH1AKA operates at peak performance. This reflects GE’s long – standing reputation for delivering reliable and high – quality industrial automation products.