Description

Product Overview

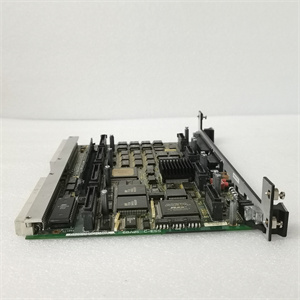

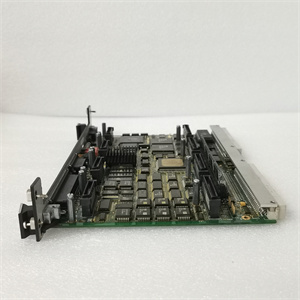

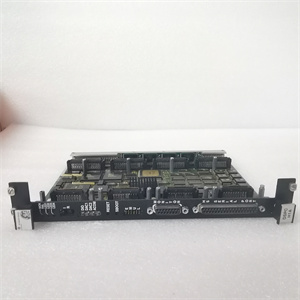

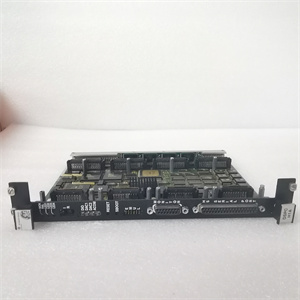

The GE DS200DSPCH1ADA is a high – performance digital signal processor control board, part of GE’s renowned Mark V series. Engineered by General Electric, a leader in industrial technology, this board is designed to meet the complex demands of modern industrial automation and control systems, especially those related to steam and gas industrial turbines.

It serves as a crucial component within the Mark V Speedtronic control system, offering significant communication bandwidth and robust processing capabilities. This allows it to directly manage power converter applications and high – performance drives in the system. With expandable inputs and outputs, the GE DS200DSPCH1ADA provides the flexibility needed to interface with a wide range of industrial devices. It can handle various signals, thanks to the daughterboards that perform functions like signal scaling, buffering, isolation, and conditioning, making the signals suitable for processing by the board’s digital signal processor. Overall, it plays a vital role in ensuring the efficient operation of industrial processes by accurately processing and controlling signals, thereby enhancing system reliability and productivity.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200DSPCH1ADA |

| Manufacturer | General Electric |

| Product Type | Digital Signal Processor Control Board |

| Series | Mark V |

| Function | Signal processing, control in industrial systems |

| Compatibility | Compatible with GE’s Mark V Speedtronic control system for steam and gas industrial turbines |

| Input/Output | Expandable inputs and outputs |

| Number of Daughterboards | Multiple (for signal conditioning etc.) |

| Backplane Connectors | 2 (on rear edge) |

| Front – faceplate Features | Multiple I/O types, LED indicators, reset button, 2 set screws for rack – mounting |

| Country of Origin | United States |

| Weight | 0.48 kg |

| Dimensions | 4 x 18.6 x 26.1 cm |

DS200DSPCH1ADA

Main Features and Advantages

High – Performance Signal Processing

The GE DS200DSPCH1ADA is equipped with advanced digital signal processing capabilities. It can rapidly and accurately process a diverse range of signals, which is crucial for applications such as controlling the precise operation of industrial turbines. By precisely analyzing and acting on signals related to turbine speed, temperature, and pressure, it ensures optimal performance and efficiency. This high – speed processing also enables quick response times to any changes in the system, minimizing the risk of disruptions.

Expandable I/O Configuration

With its expandable inputs and outputs, the board can be tailored to fit different industrial setups. Whether it’s connecting to a large number of sensors for data collection or actuators for control purposes, the GE DS200DSPCH1ADA can be configured accordingly. This adaptability makes it suitable for a wide variety of applications, from small – scale industrial processes to large – scale power generation plants. It reduces the need for multiple different boards in a system, simplifying the overall architecture and potentially lowering costs.

Signal Conditioning Daughterboards

The inclusion of daughterboards for signal scaling, buffering, isolation, and conditioning is a significant advantage. These daughterboards ensure that the signals reaching the digital signal processor are in the proper format and quality. Signal isolation, for example, protects the board from electrical interference, enhancing its reliability in noisy industrial environments. The conditioning process also helps in improving the accuracy of signal processing, leading to more stable and reliable control of industrial equipment.

Application Field

Power Generation

In power plants with steam and gas turbines, the GE DS200DSPCH1ADA is essential. It monitors and controls various parameters related to turbine operation. For instance, it processes signals from sensors that measure the temperature and pressure of the steam or gas flowing through the turbine. Based on this processed data, it can adjust the fuel supply, control the speed of the turbine, and manage other critical functions. This ensures efficient power generation, reduces energy waste, and helps in maintaining the long – term health of the turbine equipment.

Industrial Manufacturing

In manufacturing facilities, the board is used in automated production lines. It can control the movement of robotic arms, conveyor belts, and other machinery. By processing signals from sensors placed on these devices, such as proximity sensors on conveyor belts or position sensors on robotic arms, the GE DS200DSPCH1ADA can ensure smooth and accurate operation. This improves production quality, increases throughput, and reduces the likelihood of errors or equipment failures.

Oil and Gas Industry

Within the oil and gas sector, this board is deployed in processes like oil refining and gas processing. It can be used to control pumps, compressors, and other equipment in pipelines. By processing signals related to pressure, flow rate, and temperature in the pipelines, it can prevent over – pressure situations, leaks, and other potential issues. This helps in ensuring the safe and efficient transportation and processing of oil and gas products.

DS200DSPCH1ADA

Related Products

- GE DS200ADMAH1AAA: Likely another module in the Mark V series. It may have different functions, perhaps focused more on analog – to – digital conversion or handling a different set of signals compared to the GE DS200DSPCH1ADA which is centered around digital signal processing and control.

- GE DS200PMCBG1AKG: This could be a power – related module. It might work in tandem with the GE DS200DSPCH1ADA, providing the necessary power supply for the digital signal processor board to function correctly within the industrial control system.

- GE IS200ICBDH1ABB: It may be an interface – related board. It could be used to connect the GE DS200DSPCH1ADA to other components in the system, expanding its connectivity options and enabling communication with a broader range of industrial devices.

- GE DS200TCQAG1BFD: This might be a module related to temperature or other environmental parameter control. It could complement the GE DS200DSPCH1ADA in applications where precise environmental monitoring and control are required, such as in turbine – based systems where temperature can significantly affect performance.

- GE DS200EXPSG1ABB: Potentially an expansion or extension module. It could be used to further enhance the capabilities of the GE DS200DSPCH1ADA, for example, by adding more input or output channels or providing additional processing power for specific tasks within the industrial control setup.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200DSPCH1ADA, ensure that all power to the relevant system components has been safely removed to prevent the risk of electrical shock or damage to the board. Thoroughly inspect the board for any visible signs of physical damage during transit. Check the rack system where it will be installed to make sure it is clean, free of debris, and properly grounded. Familiarize yourself with the location and function of all the connectors, buttons, and set screws on the board. When replacing an existing board, note the settings and connections of the old board for accurate replication on the new GE DS200DSPCH1ADA.

Maintenance recommendations: Regularly clean the GE DS200DSPCH1ADA to remove dust and debris, as these can accumulate over time and potentially affect the performance of the board, especially in terms of heat dissipation and electrical conductivity. Periodically check the status of the LED indicators on the front – faceplate to monitor the board’s operational health. If any LEDs show abnormal behavior, refer to the product manual for troubleshooting steps. Also, keep an eye on the system’s overall performance; if there are any sudden changes in the operation of the equipment controlled by the board, it could indicate a problem with the GE DS200DSPCH1ADA. In such cases, perform a detailed diagnostic check, which may involve testing the input and output signals and ensuring proper communication with other connected components.

Product Guarantee

General Electric offers a comprehensive product guarantee for the GE DS200DSPCH1ADA. The board comes with a standard warranty period, during which any manufacturing defects will be rectified by GE free of charge. Their global network of technical support teams is available to assist customers with installation guidance, configuration advice, and troubleshooting. In case of any issues, customers can rely on GE’s expertise to quickly resolve problems and ensure the continued operation of their industrial systems. This commitment to quality and after – sales service reflects GE’s confidence in the reliability and performance of the GE DS200DSPCH1ADA in demanding industrial environments.