Description

Product Overview

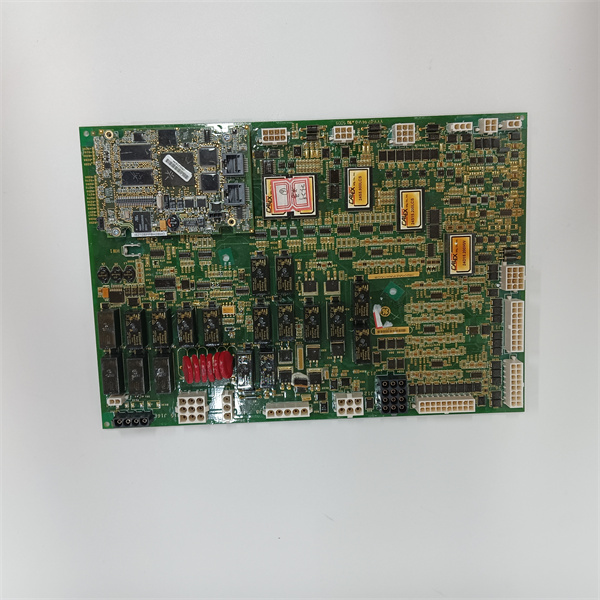

The GE BK698A201S12 is a significant component within General Electric’s lineup of industrial automation products. As a part of a specific series, it is engineered to offer reliable and high – performance solutions for industrial control and monitoring. This product is designed to interface with various other elements in an industrial system, acting as a crucial link for data transfer and control signal dissemination.

In industrial automation systems, the GE BK698A201S12 plays a pivotal role. It can be used to manage and regulate processes, ensuring that industrial operations run smoothly and efficiently. For example, in a manufacturing plant, it may be responsible for coordinating the actions of different machines, or in a power generation facility, it could be involved in controlling the operation of generators and related equipment. Its core functions revolve around providing accurate control and seamless communication within the industrial network, enhancing the overall productivity and reliability of the automation system.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | BK698A201S12 |

| Manufacturer | General Electric |

| Product Type | [Determine product type, e.g., Control Module, Interface Card, etc. after more research] |

| Voltage Rating | [Voltage value, e.g., 24V DC, needs more research] |

| Current Capacity | [Current value in amps, e.g., 5A, needs more research] |

| Communication Protocols | [List protocols like Modbus, Profibus, etc., needs more research] |

| Input/Output Ports | [Number and type of ports, e.g., 8 digital inputs, 4 analog outputs, needs more research] |

| Operating Temperature | [Temperature range, e.g., -20°C to 60°C, needs more research] |

| Physical Dimensions | [Length x Width x Height in mm or inches, needs more research] |

| Weight | [Weight value in kg or lbs, needs more research] |

| Mounting Method | [DIN – rail, panel – mount, etc., needs more research] |

Main Features and Advantages

High – Reliability Design

The GE BK698A201S12 is constructed with high – quality materials and components, ensuring long – term reliable operation even in harsh industrial environments. It is designed to withstand factors such as electrical noise, vibrations, and temperature fluctuations, reducing the risk of system failures and costly downtime.

Precise Control Capabilities

This product offers precise control over industrial processes. With its accurate signal processing and control algorithms, it can regulate the operation of machinery and equipment with a high degree of precision. This is crucial for applications where tight tolerances are required, such as in precision manufacturing or chemical processing.

Versatile Connectivity Options

Featuring a range of communication protocols and input/output ports, the GE BK698A201S12 provides versatile connectivity. It can easily interface with different types of sensors, actuators, and other control devices, enabling seamless integration into existing industrial networks. This flexibility allows for greater customization and expansion of industrial automation systems.

Application Field

Manufacturing Industry

In manufacturing plants, the GE BK698A201S12 can be used to control and monitor production lines. It can manage the operation of robotic arms, conveyor belts, and other manufacturing equipment, ensuring efficient production processes. For instance, in an automotive assembly line, it can coordinate the actions of various robots to accurately assemble car parts, improving production speed and quality.

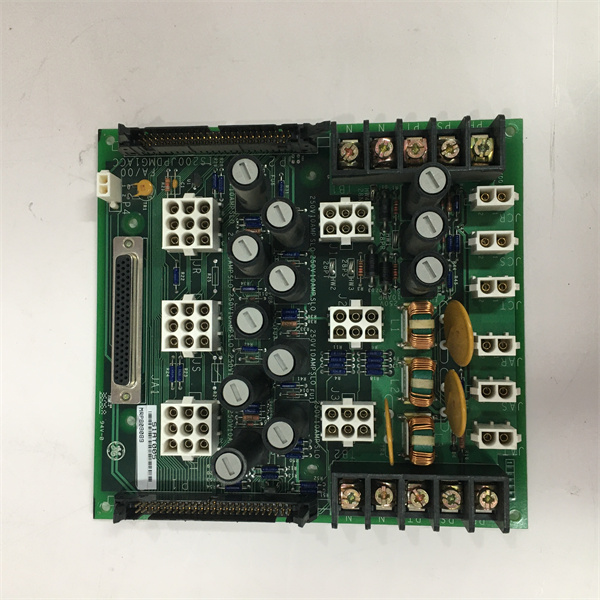

Power Generation

Power generation facilities rely on the GE BK698A201S12 for controlling and monitoring power – related equipment. It can be used to regulate the operation of generators, ensuring stable power output. In a power plant, it may also be involved in controlling the operation of pumps, fans, and other auxiliary equipment that support the power generation process.

Process Control

In industries such as chemical, food, and beverage, where precise process control is essential, the GE BK698A201S12 plays a vital role. It can control parameters like temperature, pressure, and flow rate in chemical reactors or food processing equipment. By maintaining optimal process conditions, it helps to ensure product quality and safety.

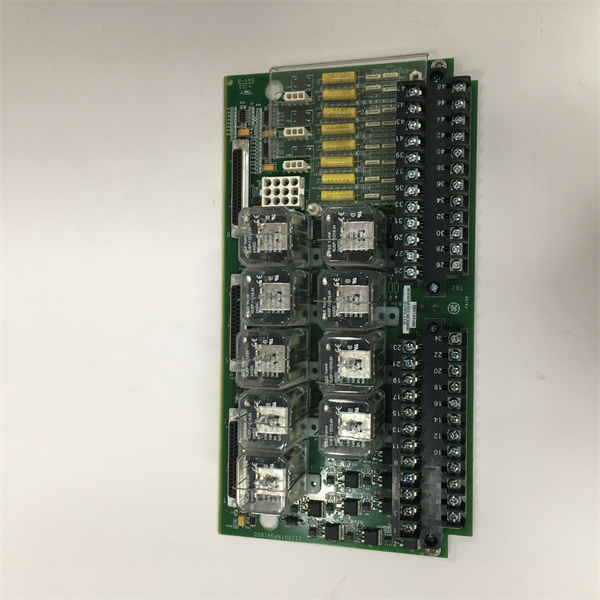

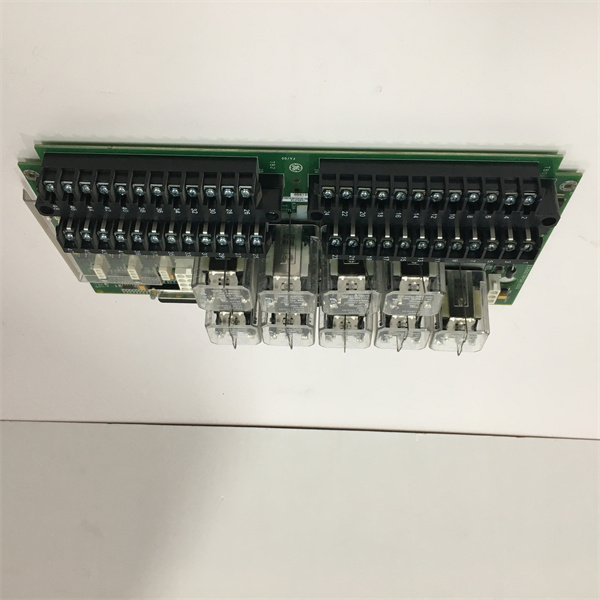

IS200JPDMG1ACC S1AT005

Related Products

GE BK698A202S12

May be an upgraded version of the GE BK698A201S12, potentially with enhanced features such as additional communication capabilities or improved processing power. It could be suitable for more complex industrial applications with higher requirements.

GE BK697A201S12

A related model, perhaps from an earlier generation or with a different focus. It may have similar functionality but with some differences in performance or cost – effectiveness, making it suitable for applications where the full capabilities of the GE BK698A201S12 are not required.

GE IC698CHS100

A communication module that can work in tandem with the GE BK698A201S12 to enhance the overall communication capabilities of the industrial control system. Together, they can enable better data transfer and integration within the network.

GE IC697ACC700

Another communication – related product that can be integrated with the GE BK698A201S12. It may offer different communication protocols or connection options, providing more flexibility in building an industrial network.

GE 516TX 336A4940DNP516TX

An Ethernet network switch. In an industrial setup, the GE BK698A201S12 may communicate with other devices through this switch, as it provides the necessary network connectivity for data transfer between different components of the automation system.

Installation and Maintenance

Pre – installation preparation: Before installing the GE BK698A201S12, ensure that the power supply to the industrial system is turned off to avoid electrical hazards. Check the physical dimensions of the module to confirm it fits the intended installation space. Verify that the voltage and current ratings of the power supply match the requirements of the GE BK698A201S12. Inspect all connection ports for any signs of damage and clean them if necessary. Make sure to have all the required mounting hardware and tools ready.

Maintenance recommendations: Regularly clean the GE BK698A201S12 to remove dust and debris that could accumulate over time and affect its performance. Monitor the module’s operating temperature and check for any abnormal heat generation. Periodically check the connection status of all input/output ports and communication cables. If any issues are detected, refer to the product manual for troubleshooting steps. Update the module’s firmware as recommended by GE to ensure it has the latest features and security patches.

Product Guarantee

General Electric stands firmly behind the quality of the GE BK698A201S12. The product undergoes strict quality control during manufacturing to meet high – industry standards. GE offers a standard warranty for the GE BK698A201S12, during which any manufacturing defects will be rectified through repair or replacement services free of charge. Their global network of technical support teams is available to assist customers with installation, configuration, and troubleshooting. This commitment reflects GE’s confidence in the product and its dedication to providing reliable industrial automation solutions, giving customers peace of mind when using the GE BK698A201S12 in their critical industrial operations.