Description

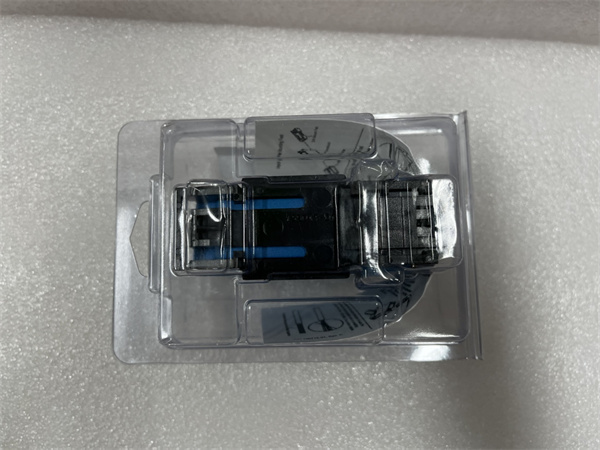

BENTLY NEVADA 330180-51-00

1. Product Description

TheBENTLY NEVADA 330180-51-00 is an 8 mm Proximitor® sensor designed for non-contact eddy current vibration and displacement monitoring of rotating machinery. As part of the 3300 XL Series, this sensor converts distance measurements into proportional analog signals, enabling real-time condition assessment of shafts, bearings, and machinery components. It supports dynamic vibration analysis, static position monitoring, and speed measurements, making it ideal for critical applications in oil & gas, power generation, and manufacturing.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Measurement Type | Vibration, displacement, shaft speed |

| Probe Diameter | 8 mm (0.315 inches) |

| Linear Range | 0.51–9.53 mm (0.020–0.375 inches) |

| Output Signal | 4–20 mA analog |

| Power Supply | 18–36 VDC (via Proximitor system) |

| Temperature Range | -40°C to +121°C (-40°F to +250°F) |

| RFI/EMI Immunity | High resistance without shielded conduit |

| Mounting Options | DIN rail or panel mount |

| Dimensions | 8.13 cm × 6.12 cm × 6.35 cm |

| Weight | 0.25 kg |

BENTLY 330180-51-00

3. Advantages and Features

- Non-Contact Design: Eliminates mechanical wear and ensures long-term reliability.

- API 670 Compliance: Meets American Petroleum Institute standards for accuracy and stability.

- Interchangeability: Probe, extension cable, and sensor components are fully interchangeable without recalibration.

- Harsh Environment Tolerance: Operates in extreme temperatures and high-vibration settings.

- Space-Saving DIN Mount: Simplifies installation in compact control panels.

4. Application Areas and Cases

- Oil & Gas: Monitoring compressor shaft alignment in offshore platforms.

- Power Generation: Detecting turbine bearing wear in thermal power plants.

- Manufacturing: Tracking conveyor belt pulley vibrations in steel mills.

- Case Study: A Middle Eastern petrochemical plant reduced maintenance costs by 30% using the 330180-51-00 to predict pump seal failures.

5. Competitor Comparison

- Higher Accuracy: ±0.1% linearity compared to industry-standard ±0.5%.

- Extended Compatibility: Works with BENTLY 3300/3500 systems and third-party controllers.

- Cost-Effective Installation: Reduces labor costs with plug-and-play DIN rail mounting.

BENTLY 330180-51-00

6. Selection Recommendations

- Probe Size: Choose 8 mm for standard applications; use 5 mm probes for confined spaces.

- Temperature Requirements: Opt for ETR (Extended Temperature Range) models for -55°C to +177°C environments.

- Safety Compliance: Verify ATEX/IECEx certifications for hazardous zones.

7. Precautions

- Cable Shielding: Use twisted-pair, shielded cables to prevent signal interference.

- Gap Setting: Maintain 1.5–2 mm probe-to-target gap for optimal performance.

- Calibration: Perform annual checks using BENTLY’s 3500 System Software.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.