Description

Product Overview

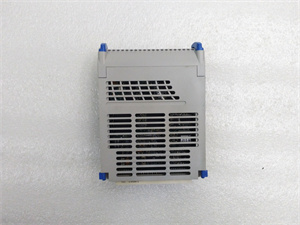

The GE IS220PRTDH1A is a high – precision Resistance Temperature Device (RTD) input module, designed as an integral part of the GE Mark VIe Speedtronic system. As a product of General Electric, a globally recognized leader in industrial technology, the IS220PRTDH1A is engineered to meet the exacting demands of industrial temperature monitoring and control.

This module serves as a crucial interface between RTD sensors and the control system. It accurately converts the resistance signals from RTDs into digital temperature values, providing reliable data for industrial processes. With its ability to handle multiple RTD inputs, the IS220PRTDH1A enables comprehensive temperature surveillance across various industrial applications. Whether it’s in a power generation plant monitoring turbine temperatures or a manufacturing facility controlling production processes, the IS220PRTDH1A plays a vital role in ensuring optimal operations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PRTDH1A |

| Manufacturer | GE |

| Product Type | RTD Input Module |

| Number of Channels | 8 |

| Input Signal Type | Resistance from RTD sensors |

| A/D Converter Resolution | 14 – bit |

| Common – mode Voltage Range | ±5 volts |

| Maximum Lead Resistance | 15 Ω |

| Power Supply | 28 VDC, 0.24 A |

| Operating Temperature Range | 0 °C to +65 °C |

| Weight | Approximately 4.40 pounds (without packing materials) |

| Dimensions | 34 x 18 x 10 cm |

| Mounting Type | DIN rail |

| Certifications | CE marked, UL listed |

Main Features and Advantages

High – Precision Measurement

The IS220PRTDH1A utilizes advanced signal – processing algorithms and a 14 – bit A/D converter, ensuring highly accurate temperature measurements. It can precisely detect temperature changes, with an accuracy of ±0.1% of full scale. This precision is crucial in industries like semiconductor manufacturing and pharmaceuticals, where even minor temperature variations can impact product quality significantly.

Robust and Reliable Design

Built to withstand harsh industrial environments, the module features a rugged construction. It can endure vibrations, electrical noise, and temperature fluctuations. In power plants or oil refineries, where equipment is exposed to challenging conditions, the IS220PRTDH1A maintains stable operation, reducing the risk of system failures and costly downtime.

Versatile Compatibility

It is compatible with a variety of RTD input terminal boards, such as TRTDH1D, H2D, and SRTD. This versatility allows for seamless integration into different industrial setups. Whether used in a new installation or as part of an existing system upgrade, the IS220PRTDH1A can be easily configured to work with the available terminal boards, providing flexibility for system integrators.

Fault Detection and Isolation

The module is equipped with an intelligent fault – detection system. It can quickly identify issues such as sensor failures, communication problems, or abnormal temperature readings. When a fault is detected, it isolates the affected channel, preventing the problem from spreading and ensuring the continued operation of the overall system. This feature is invaluable in maintaining the integrity of industrial processes.

Application Field

Power Generation

In power plants, the IS220PRTDH1A is extensively used to monitor the temperature of critical components in gas and steam turbines. By accurately measuring the temperature of turbine blades, bearings, and combustion chambers, it helps optimize the turbine’s performance, ensuring efficient power generation. For example, in a gas – fired power plant, precise temperature control enables better fuel – air mixing, reducing emissions and increasing overall efficiency.

Manufacturing

Manufacturing industries rely on the IS220PRTDH1A for temperature control in numerous processes. In food and beverage production, it ensures the proper temperature during baking, brewing, and pasteurization, maintaining product quality and safety. In metal – working factories, the module monitors the temperature of furnaces, molds, and cooling systems, enabling precise control of manufacturing processes and minimizing defects in the final products.

Oil and Gas

The oil and gas sector benefits from the IS220PRTDH1A in multiple ways. It is used to monitor the temperature of pipelines, storage tanks, and processing equipment. In offshore oil rigs, where environmental conditions are harsh, the module’s reliable temperature measurement helps detect potential issues such as pipeline blockages or equipment malfunctions. By providing real – time temperature data, it enables timely interventions to prevent costly disruptions to production.

Related Products

GE IS230SNRTH2A

This is another RTD input module from GE. While the IS220PRTDH1A is part of the Mark VIe Speedtronic system, the IS230SNRTH2A may have different features, such as a different number of input channels or a different focus in terms of application scenarios. It can be used in complementary ways in some industrial setups, providing additional temperature – monitoring capabilities.

GE IS220PDIAH1A

A digital input module, distinct from the temperature – focused IS220PRTDH1A. The IS220PDIAH1A is designed to receive digital signals from various sources like switches and sensors with digital outputs. In an industrial control system, it can work in tandem with the IS220PRTDH1A, where the temperature data from the IS220PRTDH1A and the digital status information from the IS220PDIAH1A are integrated and processed by the overall control system.

GE IS220PDOAH1A

A digital output module that sends digital control signals to actuators, relays, or other devices. In an industrial process, the control system may use the temperature information from the IS220PRTDH1A to make decisions and then send out control commands through the IS220PDOAH1A to adjust equipment operations.

GE IS200SRTDH2A

Also an RTD – related module, but it might have different characteristics compared to the IS220PRTDH1A. It could have a different level of accuracy, a different number of input channels, or be optimized for a specific type of industrial application. For instance, it might be more suitable for applications where a different range of RTD sensors need to be supported.

GE IS220UCSAH1A

This module likely has different functions from the IS220PRTDH1A. It could be involved in overall control logic implementation or other aspects of the industrial control process. In a complex industrial control system, the IS220PRTDH1A and the IS220UCSAH1A can collaborate, with the IS220PRTDH1A providing temperature data and the IS220UCSAH1A using that data to execute specific control algorithms.

Installation and Maintenance

Pre – installation preparation: Before installing the IS220PRTDH1A, ensure the power to the industrial control system is turned off. Thoroughly clean the area where the DIN rail will be installed to prevent dust or debris from interfering with the module’s performance. Check the compatibility of the IS220PRTDH1A with other components in the system, referring to GE’s official documentation. Verify that the power supply voltage is stable and within the specified range of 28 VDC. Mount the DIN rail securely in the control cabinet, following the provided installation instructions. Then, carefully slide the IS220PRTDH1A onto the DIN rail until it is firmly in place.

Maintenance recommendations: Regularly inspect the IS220PRTDH1A for any signs of physical damage, such as cracks on the module’s casing or loose connections. Monitor the temperature readings it provides to ensure they are within the expected range for the industrial process. If there are any abnormal fluctuations, it could indicate a problem with the module or the RTD sensors. Clean the module gently, if necessary, using a soft, dry brush to remove any accumulated dust. Periodically check the DIN rail mounting to ensure the module is still securely attached. If any issues are detected, consult GE’s technical support or the product’s troubleshooting guide for proper diagnosis and repair.

Product Guarantee

GE stands firmly behind the quality of the IS220PRTDH1A. The module is manufactured using high – quality components and undergoes rigorous testing to meet strict industry standards. GE offers a standard warranty period for the IS220PRTDH1A, during which, if the module experiences any defects in materials or workmanship, GE will provide repair or replacement services free of charge. Their team of experienced technical support professionals is available 24/7 to assist customers with any installation, operation, or maintenance questions. GE’s commitment to quality and after – sales service ensures that customers can rely on the IS220PRTDH1A for long – term, reliable performance in their industrial applications, giving them peace of mind and confidence in their investment.